In commercial refrigeration systems, the compressor acts as the core of the cooling process. It pushes refrigerant through the entire setup under strong pressure. A breakdown in this key part—particularly burnout—can cause complete shutdowns and costly interruptions in equipment use. Compressor burnout goes beyond a simple technical glitch. It endangers food safety, boosts energy expenses, and interrupts store activities.

Why Do Electrical Failures Lead to Compressor Burnout?

One frequent source of compressor trouble comes from voltage imbalance. In three-phase compressors, when power levels at the terminals vary, the current pull becomes uneven. As a result, specific spots in the motor windings heat up too much. Without quick fixes, this unevenness breaks down the insulation and brings about burnout in the end.

Phase loss makes matters worse. For three-phase setups, if one phase fades or gets weak, the compressor keeps running but poorly. It pulls too much current from the other phases. This extra heat load quickly wears out the winding insulation. In turn, it can spark a major breakdown.

Control system malfunctions cause short cycling which stresses components

Yet another electrical problem involves short cycling. Here, the compressor switches on and off far too often. This odd pattern stops enough oil from returning to the crankcase. Consequently, friction in mechanical parts rises. Thermostat errors or bad relays often trigger this. Over time, it speeds up damage to motor bearings and valves.

Loose wires and damaged insulation lead to arcing and internal failure

Bad electrical links, like loose ends or rusted contact spots, spark power surges and sparks. Such sparks bring intense heat that harms nearby parts. Moreover, worn-out insulation lets current escape between windings or to the frame. Eventually, this shorts the motor and causes damage inside.

What Mechanical Conditions Accelerate Compressor Burnout?

A properly oiled compressor cuts down on wear for pistons, valves, and bearings. However, if oil runs low from neglect or drips, direct metal contact happens. This builds up mechanical strain, leading to excess heat and lock-up over periods of use. Oil quality suffers from refrigerant mixing or water intrusion, too. During floodback, when the refrigerants blend with oil, the oil thins out. Thus, it loses its shielding ability against wear.

Contaminants obstruct oil pathways and chemically degrade internal parts

Wear from mechanics or failed desiccants creates tiny bits that block slim oil routes. Water in the cooling loop might form acids with the refrigerant as well. This harsh blend eats away at copper windings and metal areas inside.

Refrigerant return in liquid form destroys valves and cools windings too rapidly

Floodback happens when liquid refrigerant flows back to the compressor in light-load times or when idle. It chills motor windings suddenly and harms valves. In bad situations, liquid slugging strikes hard. Incompressible liquid floods the cylinder, shattering parts within.

How Does Heat Management Failure Result in Burnout?

Condenser coils covered in grime or lacking good air flow block heat release. Since heat stays trapped, the output pressure climbs. This adds a burden to the compressor and heats its insides. Eventually, it passes safe heat levels.

Extreme ambient temperatures affect refrigerant behavior and motor load

Hot surroundings cut the system’s chill power. At the same time, they lift the suction pressure and current use. On the flip side, cold surroundings during rest periods let refrigerant shift into the compressor housing. This leads to flooded starts, causing instant harm right away.

Internal overload protectors often fail before saving the system

Most compressors include heat overload guards to halt work when temperatures soar. Yet, if these guards break down or prove too small for the job, they might not cut power soon enough. Therefore, the unit runs too long in risky heat. This slowly ruins winding insulation through ongoing exposure.

Are Design and Installation Errors Putting Compressors at Risk?

Fitting compressors that don’t match the workload leads to nonstop full-speed running. This hastens overall wear. Units that are too big cycle too much instead. That pattern also pushes toward early burnout through repeated strain.

Piping errors and charge issues affect oil return and cooling capacity

Wrong suction line setups hinder oil flow back or let liquid refrigerant reach the compressor. Extra refrigerant or too little throws off the pressure equilibrium in the system. Both problems cut cooling effectiveness and heighten stress on the compressor during operation.

Skipping commissioning steps allows air ingress and moisture retention

Teams that bypass vacuum pulls before adding refrigerant leave water behind. This leftover moisture reacts with refrigerants to make acids. Those acids chew through the inside parts gradually. Failed leak checks let air sneak in, too. Over months, this worsens the chemical harm inside the system.

Can Maintenance Gaps Be the Silent Cause Behind Compressor Burnout?

Every three months, preventive upkeep remains crucial. It covers looking at terminal firmness, tracking amp pulls, confirming refrigerant amounts, and assessing oil state. Without these steps, tiny glitches grow into big breakdowns that halt everything.

Overlooking performance anomalies can hide early burnout symptoms

Plenty of alerts show up before compressor burnout hits. You might hear strange sounds at start-up, feel hot output lines, notice odd on-off patterns, or see jumps in power use. Brushing off these clues postpones fixes. As a result, damage builds until repair becomes urgent and expensive.

Dirty coils force compressors to work harder than necessary

Grimy evaporators limit heat pickup from the space. Clogged condensers stop heat from leaving properly. In each case, the compressor pushes extra to keep up. This means longer runs at higher heat, which tires out parts faster than normal.

Do Environmental Conditions Contribute to Compressor Degradation?

High dampness seeps into seals that aren’t tight, or units opened for repairs. When it mixes with refrigerants, it creates hydrochloric or hydrofluoric acid. These substances harm motor windings steadily over extended exposure.

Corrosive air from coastal regions attacks metal parts and terminals

Coastal spots carry salty air that speeds up rust on open metals like terminal setups or copper lines. This rust builds resistance in electrical paths. It also weakens the build of those parts, leading to failures down the line.

Create Refrigeration’s Commitment to Quality Equipment Solutions

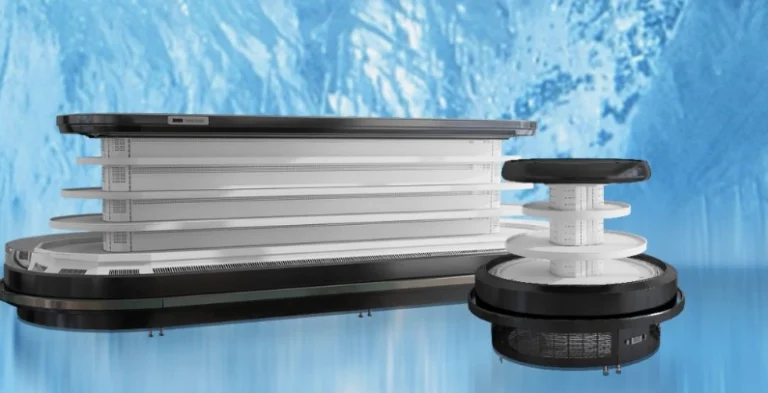

Selecting refrigeration setups built for lasting results calls for a trusted maker. Shandong Create Refrigeration Co., Ltd., based in Xingfu Industrial Park, Binzhou City, China, stands as China’s top all-in-one buyer source for supermarkets and project needs. Their range covers multideck chillers, island freezers, cold storage rooms, and glass-door display cabinets. All are crafted for steady work in various settings around the world. Smart designs add to reliable runs. Units feature strong air barriers, robust fan motors, copper tube evaporators, dense insulation boards, and variable speed options. These cut power costs while keeping things cool.

Check out options such as their Supermarket Combined Island Freezer or Multideck Refrigerated Open Chiller Cabinet. Both aid low-power use and provide clear views of goods inside for better sales appeal. With approvals like CE, CB, ETL, ROHS, UL, IEC—and reach to more than 70 nations—Create Refrigeration serves as a solid choice for supermarkets needing tough cold chain tools that last through challenges.

Key Takeaways on Preventing Compressor Burnout in Refrigerators/Freezers

Compressor burnout arises from blended issues. Electrical glitches, such as voltage mismatches, play a big part. Mechanical pressures from weak oiling or dirt add to it. Heat problems, like faulty condenser cooling, worsen the strain. Bad setups, including wrong sizes or pipe layouts, invite trouble. Missed upkeep, such as ignoring coil dirt, lets risks grow. Outside factors, from dampness to salty winds, speed up decay, too.

To avoid these pitfalls and keep systems running smoothly, several steps can help greatly. First, plan setups with exact capacity fits to match real needs without excess effort. Next, set up units following top commissioning rules, ensuring no air or water lingers inside from the start. Then, set regular check schedules to catch issues early before they spread. Also, watch performance data all the time, using tools to spot odd patterns in power or temps. Finally, pick gear made tough for harsh spots, so it holds up against daily wear and outside threats over long periods.

FAQ

Q1: How can I tell if my refrigerator compressor is starting to fail?

A1: Look for typical clues like odd sounds while running, higher power bills from extra draw, uneven chill levels inside, constant on-off switches, or breakers flipping from overload currents that signal building stress.

Q2: What is the impact of improper refrigerant charge on compressor health?

A2: Too much refrigerant hikes up the pressure at output, forcing harder work. Too little means poor child results overall. Either way, these imbalances add undue load to compressor elements.

Q3: How often should commercial refrigeration systems be serviced to prevent compressor burnout?

A3: Aim for upkeep every quarter as a baseline to stay ahead. This routine involves tightening electrical ties, gauging refrigerant fills accurately, wiping down coils for better flow, eyeing oil for purity, and running tests on control setups to ensure everything syncs without faults.