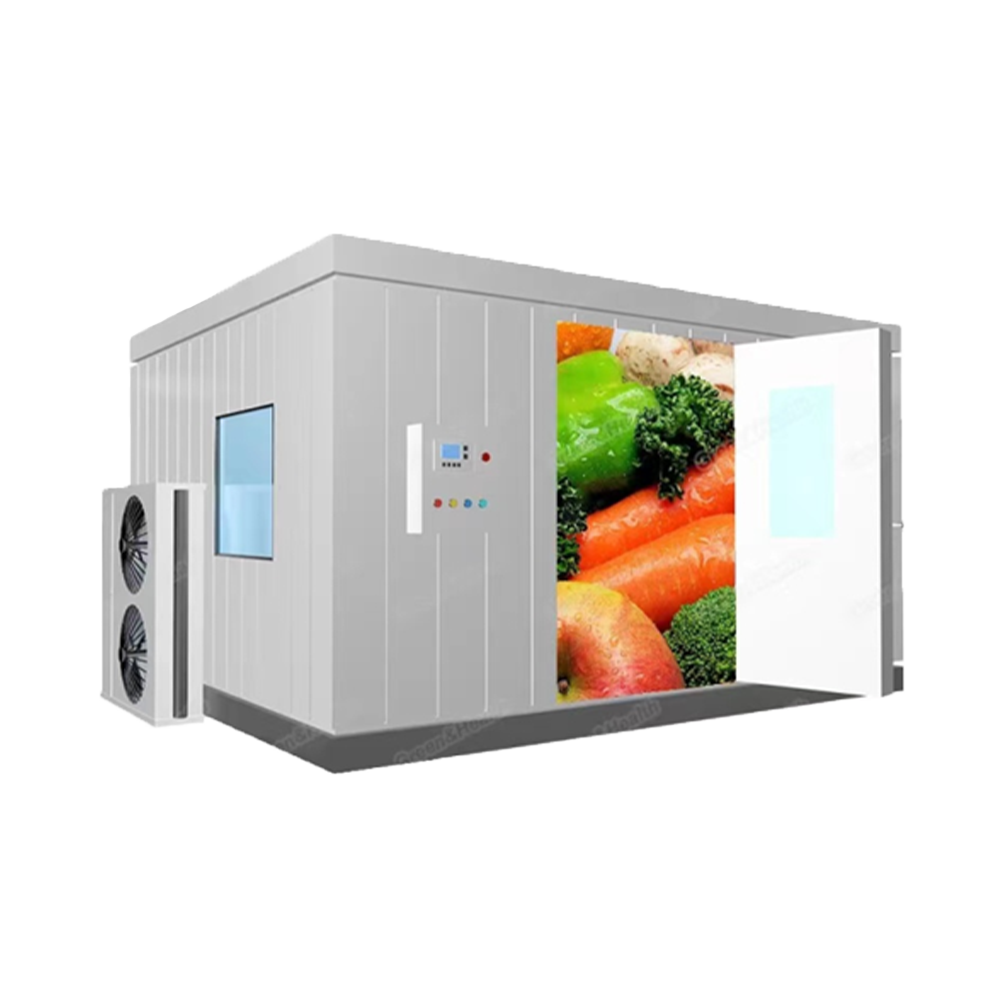

Running a business means your cooling needs can change over time. You might ask yourself: can a Walk-In Cooler turn into a Walk-In Freezer? At Shandong Create Refrigeration Co., Ltd., we get how important it is to have flexible cooling setups. These setups keep your stuff—like drinks, fruits, or frozen fish—fresh and safe. Changing a cooler to a freezer lets you store frozen things, like meat or ice cream, without shelling out for a new unit. In this straightforward guide, we’ll check out if this switch is possible, what you need to think about, and how Create Refrigeration can help with your cooling ideas.

Key Differences Between Walk-In Coolers and Walk-In Freezers

Before you try to turn a cooler into a freezer, you gotta know what makes them different. These differences in how they’re built and what they’re used for affect the changes you’ll need to make.

Temperature Needs for Coolers vs. Freezers

Walk-in coolers keep things chilly, between 0°C and 10°C. That’s great for storing drinks, water, yogurt, fruits, veggies, and stuff like that. But freezers? They’re way colder, sitting at -18°C to -22°C or even lower. They’re made to keep frozen fish, meat, or ice cream safe. The huge temperature difference means freezers need beefier cooling systems and thicker insulation.

Insulation Types and Materials

Insulation keeps the cold air locked in. Coolers use thinner foam, around 3-4 inches thick. That’s fine for light chilling jobs. Freezers, though, need chunkier foam, about 5-6 inches or more, to stop warm air from sneaking in and to hold the icy air. The foam also has to stay tough in super-cold temps without cracking.

Cooling Systems and Parts

Coolers have small motors and parts meant for gentle cooling. Freezers use bigger, stronger motors and special cooling liquids, like R404A, to hit and hold those low temps. To switch a cooler to a freezer, you’ll likely need to swap out those parts for heavier-duty ones.

These differences help you figure out if the switch is worth it. Let’s dive into what you need to think about before you start.

Factors to Consider Before Conversion

Turning a walk-in cooler into a freezer isn’t just about cranking down the temp. You gotta check the cooler’s build and how it works to make sure it fits your business.

Structural Changes Needed

Your cooler’s setup might need some tweaks to act like a freezer. Here’s what you might have to do:

- Floor Fixes: Freezers need insulated floors with non-slip surfaces. This stops frost and keeps workers from slipping.

- Door Upgrades: Cooler doors might not seal tight enough for freezers. You may need tougher doors with better seals.

- Wall Boosts: You might need to slap on thicker foam or reinforce walls. This traps cold air inside.

Energy Use and Power Needs

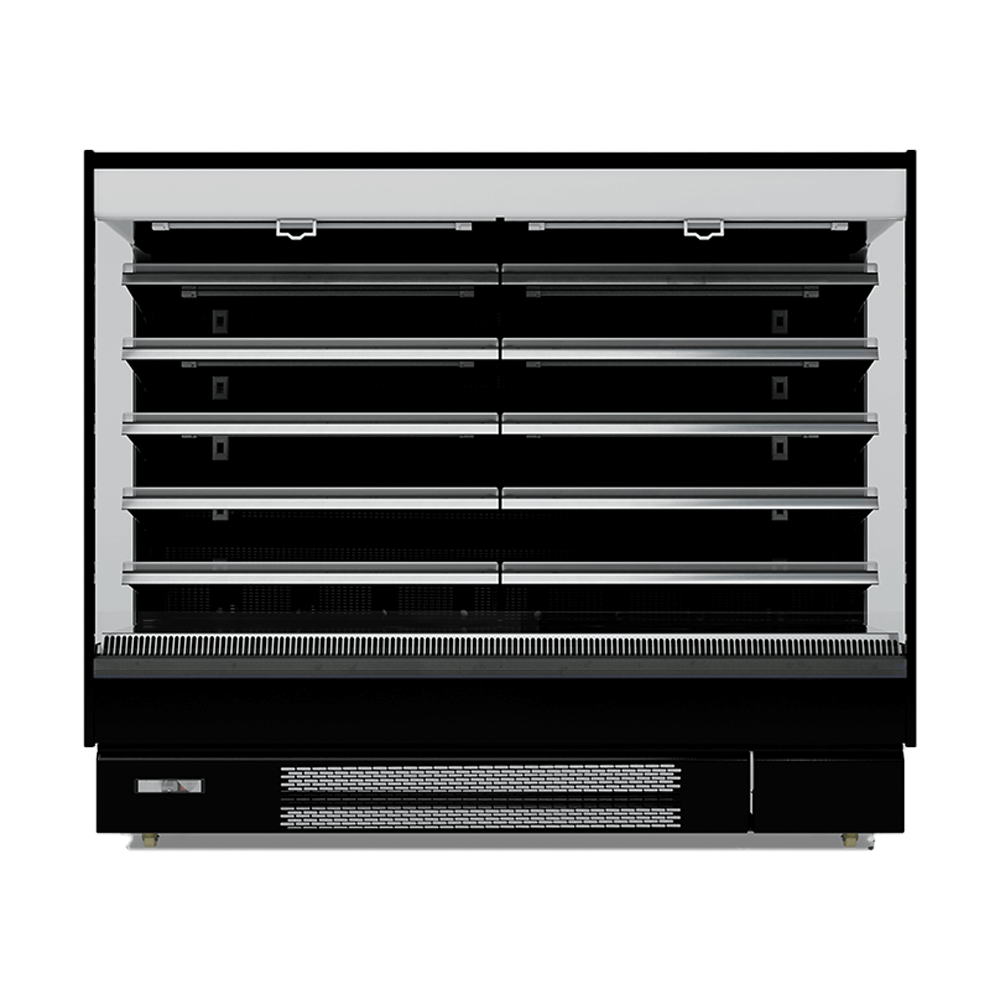

Freezers guzzle more electricity than coolers since they stay so cold. Check if your building’s power can handle the extra juice. Using energy-saving parts, like those in our Supermarket Open Chiller, can cut your bills while storing frozen stuff like ice cream.

Costs of the Switch

The price of changing a cooler depends on its shape, the upgrades you need, and new parts. You might spend cash on better foam, new cooling systems, and folks to do the work. Sometimes, switching a cooler is cheaper than buying a new freezer. But you gotta weigh the costs to see if it’s a good move.

These points help you plan a solid switch. Now, let’s go over how to make it happen.

Steps Involved in the Conversion Process

Turning a walk-in cooler into a freezer takes some serious planning and work. Here’s a no-fuss guide to get it done right.

Checking the Cooler’s Shape

First, take a good look at your cooler’s condition. Check for these things:

- Cracks or water marks on walls and floors.

- Tight seals around doors and edges.

- If the current parts can handle freezer demands.

A pro inspection, like the ones we do at Create Refrigeration, makes sure you don’t miss anything big.

Beefing Up Insulation and Sealing

To hit freezer standards, you need better insulation. Here’s what to do:

- Slap on thicker foam panels to walls, ceilings, and floors.

- Put up barriers to keep moisture out.

- Swap door seals to stop cold air from escaping.

These steps are super important to keep the freezer icy.

Installing a Freezer-Ready Cooling System

The cooling system needs a major overhaul to handle freezer temps. You’ll need to:

- Switch out the motor and cooling parts for stronger ones.

- Use a freezer-safe cooling liquid, like R404A or R507.

- Add gadgets to stop frost from piling up. This keeps frozen meat or fish fresh for longer.

With these steps done, let’s talk about some hiccups you might hit during the switch.

Potential Challenges During Conversion

Switching a cooler to a freezer can come with a few headaches. Knowing these issues upfront helps you get ready and make the switch go smoothly.

Dealing with Moisture and Wetness

Freezers can get damp inside because of their cold temps. To tackle this, you should:

- Use tough foam and barriers to stop water from forming.

- Add tools to zap frost or control wetness.

- Make sure air flows well to keep things dry.

Following Safety Rules

The new freezer has to meet standards like NSF and UL. That means you need to:

- Use safe materials for foam and floors.

- Make sure power parts follow safety rules.

- Set up safe exits and lights for workers.

Our crew at Create Refrigeration makes sure all changes stick to these rules.

Handling Downtime During the Switch

Switching the cooler might pause your work for a bit, especially if you’re using it. To keep things moving:

- Schedule the job for slow times or off-seasons.

- Grab temporary cooling units for stuff like drinks or frozen foods.

- Team up with pros to wrap up the job fast.

Getting through these hurdles sets you up for the awesome perks of the switch, which we’ll hit next.

Benefits of Converting a Walk-In Cooler to a Freezer

Turning a walk-in cooler into a freezer gives your business some sweet advantages when you need new storage options.

Making the Most of Your Space

Switching a cooler lets you use the space you already have without building more. Say an eatery wants to go from storing drinks and veggies in a cooler to keeping frozen meat and ice cream in a freezer. This lets you add new menu items without needing extra room.

Keeping Up with New Storage Needs

As your business grows, what you store might shift. Changing a cooler to a freezer lets you stash frozen fish or ice cream. This keeps up with new products or trends without the price tag of a new unit.

These perks make switching a cooler a solid move. We’re here to help you pull it off.

Create Refrigeration: Your Trusted Partner for Walk-In Coolers and Freezers

At Create Refrigeration, we’re proud to offer top-notch cooling solutions that fit your business. With 25 years of know-how and a 50,000-square-meter factory pumping out over 23,000 units a year, we serve folks in more than 70 countries.

Expertise in Custom Solutions for Refrigeration Needs

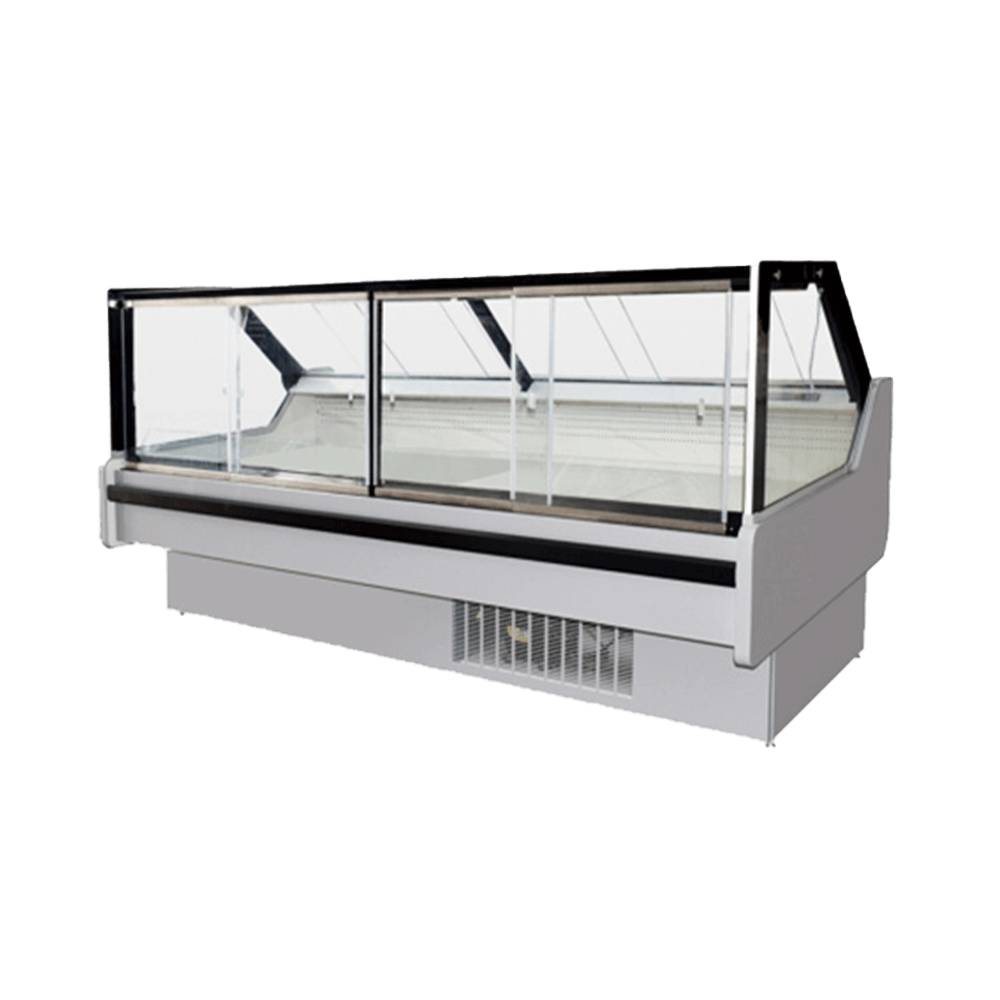

We’re pros at building walk-in coolers and freezers tailored to you. Whether you need a cooler for fruits and yogurt, like our Supermarket Dairy Fruits Display Showcase, or a freezer for frozen fish, we whip up drawings and 3D models to make sure it’s just right.

Commitment to Quality and Customer Satisfaction

Our products meet tough standards like ROHS, CE, and ISO 9001, so they’re safe, energy-saving, and good for the planet. We back plug-in units with a one-year warranty and key parts with three years. That shows we stand by our work. Need help? Just contact us.

Conclusion

Switching a walk-in cooler to a walk-in freezer is a smart play for businesses looking to store frozen fish, meat, or ice cream. By getting the differences, checking if it’s doable, and tackling any issues, you can make a great call. At Create Refrigeration, we’re ready to back you up with pro solutions and trusty products. Whether you switch your cooler or grab a new freezer, we’ll keep your business cool and humming along.

FAQs

Q1 Can any walk-in cooler be converted into a freezer?

A1 Not every cooler can make the cut. Its strength and insulation gotta meet freezer standards. You’ll need a pro to check if it’s up to snuff.

Q2 How long does the conversion process typically take?

A2 It depends on how tricky the job is. Usually, it takes a few days to a couple of weeks. Stuff like the cooler’s shape, upgrades needed, and timing can stretch it out. Our team at Create Refrigeration hustles to keep your business rolling.

Q3 Is it more cost-effective to convert or buy a new walk-in freezer?

A3 It hinges on your cooler’s condition and what your business needs. A pro check is a good idea. Switching can save bucks if the cooler’s in decent shape. But if it needs major work, a new freezer might be the better bet. Hit us up for a custom cost rundown.