The cooling speed of a commercial display freezer goes beyond just a technical detail. It also cuts down spoilage risks. Plus, it eases the compressor’s work in the long run. This leads to longer system life and better daily operations. This piece looks into the main design elements and outside factors that affect how much time a commercial freezer needs to cool down.

How Do Compressor Capacity and Refrigerant Type Impact Cooling Speed?

The compressor acts as the core of any refrigeration setup. Its strength right away shapes how fast the freezer gets to the best temperatures. Strong compressors work with more force. They enable quick cycles and speed up the chill-down process. Newer models often include adjustable-speed or inverter compressors. These help fine-tune performance for different loads. The refrigerant kind matters just as much. Create focuses on using eco-friendly R290 refrigerants. These beat out old HFCs in heat-handling abilities. With a low Global Warming Potential (GWP), R290 provides top-notch heat movement traits. This lets systems chill quicker and more evenly, even under pressure limits.

Why Does Airflow Design and Internal Circulation Matter?

Air movement inside the cabinet decides how well cold air spreads to stored items. Well-positioned fans paired with channeled air systems get rid of hot spots. They spread cool air steadily over shelves and sections. Full-circle cold air flow in the cabinet keeps temperatures steady and cooling strong. This proves vital in multideck open fridges, where products face more exposure. Better air flow not only hastens the first cool-down but also sharpens recovery after many door opens. Such opens happen often in store settings. Units like the Multideck Refrigerated Open Fridge use smart fan setups. These keep things consistent up and down the tiers. As a result, even items on high shelves stay at safe levels.

How Do Insulation Materials and Cabinet Thickness Affect Cool-down Time?

Thermal insulation builds a shield between outside warmth and the freezer’s inside. High-density polyurethane foam does a great job at blocking heat from coming in. Features like triple-pane glass doors add to this by cutting energy escape. Thus, the inside chills faster and holds steady temperatures better. Cabinet wall thickness counts too. Thicker panels slow down heat transfer, particularly in machines set up in warm areas such as kitchens or sunny store fronts.

Does Evaporator Coil Size and Placement Influence Cooling Performance?

Bigger coils give more room for this swap, which hurries the cooling along. Placing them wisely, say near air paths or behind shelves, makes sure cooling spreads evenly. It avoids stressing just one part of the unit. Defrost quality ties in closely as well. Good defrost rounds stop ice from building up. Such buildup could slow cooling and mess with air flow over time. Keeping this in check maintains smooth operations throughout.

How Does Display Configuration Impact Cooling Efficiency?

Open versus closed styles make a big difference in keeping cold in. Open-front models draw customers for easy grabs, but they let warm air sneak in, especially when it’s busy. On the other hand, closed types with sliding or hinged glass doors block that heat. They lighten the compressor’s job and keep target temps more dependably.

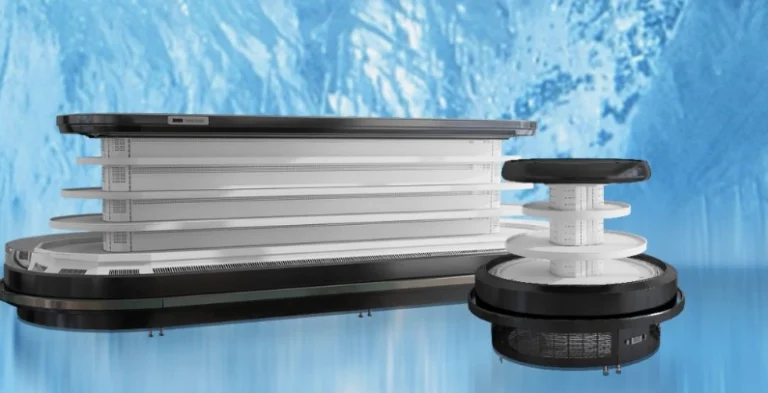

Tall multideck units need solid fan help to fight air layering. Meanwhile, flat island freezers use gravity to aid air flow. The Deep Single Island Refrigerator Freezer comes with a broad view window and tuned air movement. These make it perfect for holding cold in big supermarket setups. Lighting often gets overlooked, yet it affects things. LED lights give off less warmth than old fluorescent ones. This drops the inside heat burden while making products easier to see. Such choices add up to better overall efficiency in daily use.

Which Operational Factors Influence Cooling Speed Most Significantly?

Adding items that aren’t pre-cooled drags out the inside chill. The system spends energy on cooling that product weight instead. Experts suggest chilling goods ahead of stocking. This practice boosts the unit’s performance right from the start. Often opening doors hits the inside temp hard. Warm air rushes in each time. Helpful fixes include auto-closers or sensors that limit exposure. These keep the cold locked in better during busy shifts. The surrounding area plays a part too. Machines near stoves or air vents take longer to cool because of extra warmth nearby. Giving space around condensers helps heat escape faster. In turn, this shortens the startup phase for new or restarted units.

How Do Energy Regulations Shape Cooling Speed Engineering?

To earn ENERGY STAR® certification, freezers must hit tough pull-down goals in test setups. These rules spark new ideas in part efficiency and insulation builds. As a result, makers create gear that performs well without wasting power. The U.S. Department of Energy (DOE) and Federal Energy Management Program (FEMP) lay out base efficiency needs. These cover compressor runs, wall insulation, refrigerant picks, and defrost controls. All these elements influence how soon a unit reaches its goal temp. Compliance ensures reliable, green operations across various sites.

Why Is Create Refrigeration a Leading Force in Commercial Freezer Innovation?

SHANDONG CREATE REFRIGERATION CO.,LTD. focuses on top-notch refrigeration tools for supermarkets, small shops, and food spots. Backed by 25 years in the field and over 23,000 units made each year, they deliver custom cold chain fixes. Their work relies on smart engineering and strict checks for quality.

Take their Supermarket Combined Island Freezer. It blends efficient compressors, LED lights, variable-speed systems that cut electric costs by more than 55%, and glass covers for easy reach. From adjustable shelving that fits different layouts to custom builds for specific needs, Create Refrigeration provides worldwide cold chain answers.

How Do Design Choices Translate to Real-World Cooling Performance?

Well-made commercial display freezers use a combined method in their build. Every piece, from compressors to fans, works together to achieve quick pull-down. At the same time, they keep up toughness and power savings. This balance ensures the unit handles real demands without breaking down soon. Picking gear made for your store’s space, item types, and busy times guarantees top results all year. It matches the freezer to your exact setup, so cooling stays reliable even under pressure.

FAQ

Q1: How long does it typically take for a commercial display freezer to reach operating temperature?

A1: Depending on model design, ambient conditions, and initial load temperature, most commercial freezers reach -18°C (0°F) within 4 to 12 hours. Factors like these can shift the timeline, but proper setup keeps it on track.

Q2: Does an open-style freezer take longer to cool than a closed one?

A2: Yes. Open-style freezers allow ambient air infiltration, which extends cooling time compared to closed-door models that better retain chilled air. The difference shows up more in warm or high-use areas.

Q3: Can upgrading components like fans or lighting improve cooling speed?

A3: Absolutely. Upgrading to high-efficiency fans or switching to LED lighting reduces internal heat load and enhances airflow, both of which contribute to quicker cool-down times. These changes pay off in faster recovery and lower running costs too.