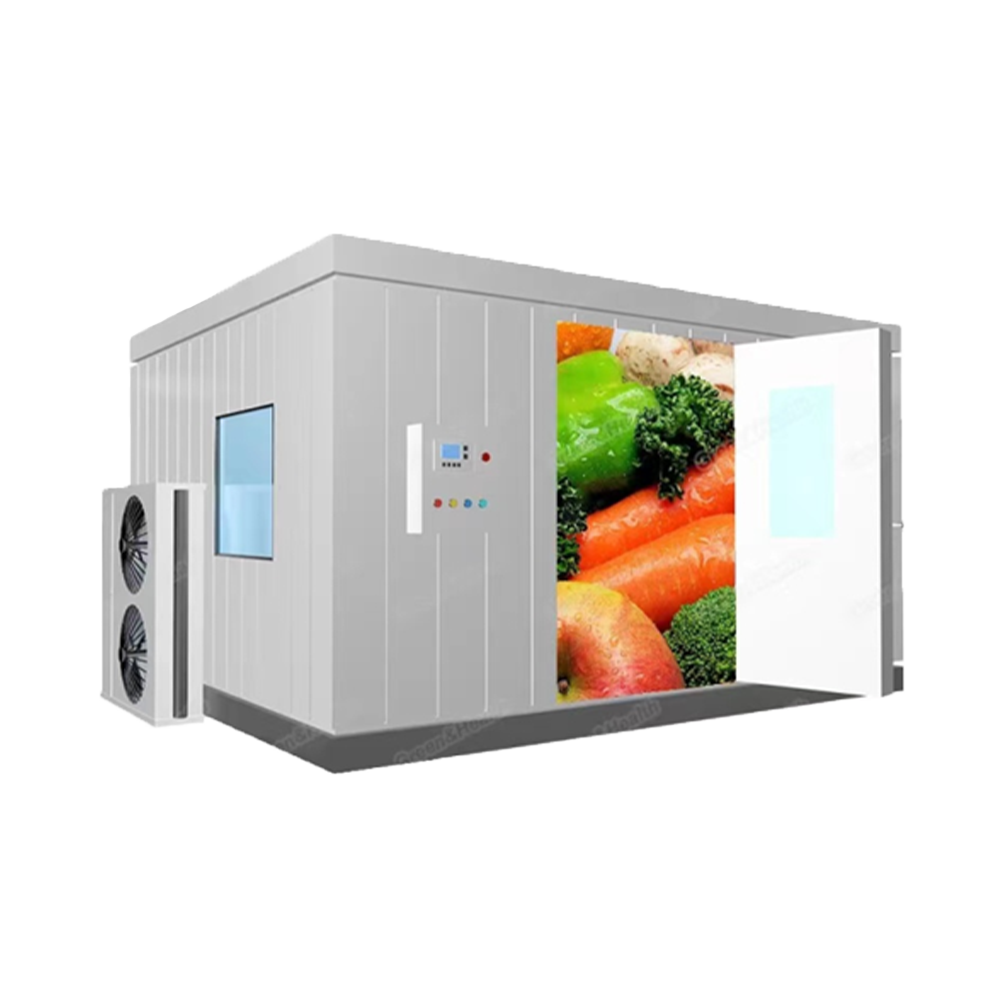

Walk-in coolers are vital refrigeration units. They store perishable items at steady temperatures. Businesses like restaurants, grocery stores, and food factories rely on them. They ensure food safety and smooth operations. Yet, the setting—indoor or outdoor—greatly shapes their design, performance, and durability.

Key Structural Differences Between Indoor and Outdoor Walk-In Coolers

Insulation is crucial for all walk-in coolers. It keeps internal temperatures consistent. However, outdoor units need thicker insulation. This protects against changing weather. Indoor units face stable conditions, so their insulation is often thinner.

Panel construction also varies. Outdoor coolers use sturdy materials. These resist damage from rain, snow, or sunlight. For example, they include rust-proof metals and strong joints. Indoor units, however, use simpler materials. They don’t face harsh elements.

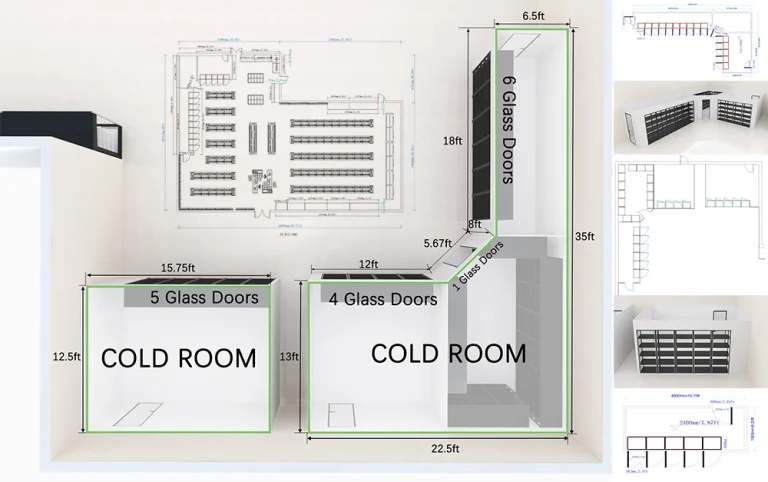

Floors differ too. Indoor coolers often sit on existing surfaces. These need little reinforcement. Outdoor units, though, have heavy-duty floors. These support large loads and block ground moisture. This design ensures long-term reliability.

Environmental Exposure and Weatherproofing Needs

Outdoor walk-in coolers face tough conditions. Rain, snow, and sun challenge their structure. So, they use waterproof seals and sun-resistant coatings. These prevent leaks and fading. Indoor units don’t need such protections. They operate in controlled settings.

Temperature swings are another issue. Outdoor coolers must maintain steady internal conditions. External weather can vary widely. Advanced controls and thick insulation help. They ensure consistent cooling. Indoor units rely on stable building environments, so this is less critical.

Ventilation needs differ too. Indoor coolers use building air systems. Sometimes, they have separate setups. Outdoor units, however, include built-in ventilation. These work independently, regardless of weather. This ensures reliable performance.

Electrical and Mechanical System Variations

Power setups vary by location. Outdoor units need weatherproof electrical boxes. They also require safe grounding to meet regulations. Indoor units have simpler power needs. They operate in protected spaces.

Compressor placement is another difference. Indoor coolers often place compressors elsewhere. This reduces noise inside. Outdoor units keep compressors close, in weatherproof cases. This makes maintenance easier. It also saves space.

Drainage is critical too. Outdoor units need sloped floors or heated drain lines. These prevent freezing in cold weather. Indoor units rarely need such features. Their environment is more predictable.

Installation Requirements Based on Location Type

Space planning matters for both types. Indoor coolers need enough room around them. This ensures good airflow and easy access for repairs. Walls, doors, and ceilings must allow clearance.

Outdoor units require more preparation. The ground must be level. A concrete base adds stability. Power sources must be nearby but follow local rules. These steps ensure safe, effective installation.

Local regulations guide decisions. They dictate what’s allowed. Consulting experts is wise. They know regional standards. This prevents costly mistakes.

Maintenance and Longevity Factors by Installation Type

Indoor coolers are easier to maintain. Accessing parts like coils or filters is simple. Outdoor units face challenges. Weather or debris can block access. Maintenance may take longer.

Component lifespan varies too. Outdoor conditions like humidity or sun wear parts faster. Compressors, seals, and panels degrade quicker outside. Indoor units face less stress, so parts last longer.

Protective steps help outdoor units. Coatings shield against weather. Shade structures block sun damage. These extend the cooler’s life. Without them, repairs increase.

Cost Implications of Indoor vs. Outdoor Walk-In Coolers

Outdoor coolers cost more upfront. They need stronger materials and weatherproof features. These add to manufacturing expenses. Indoor units are simpler and cheaper to build.

Operating costs depend on efficiency. Good insulation lowers energy use. High-quality compressors also save power. Create Refrigeration uses top-rated inverter compressors. These are efficient and reliable. They cut electricity bills significantly.

Repairs differ too. Outdoor parts face harsher conditions. They may need frequent fixes or replacements. Indoor components last longer, reducing repair costs. Planning for these expenses is smart.

Choosing the Right Walk-In Cooler for Your Business Needs

Consider your environment first. Do you have indoor space? Is outdoor access secure? Climate matters too. Outdoor units suit moderate weather with proper protections. Indoor units work best in controlled settings.

Storage needs are key. How much volume do you require? How often will staff access the cooler? These questions guide your choice. Budget is another factor. Higher-quality units cost more initially. Yet, they save money over time. Lower energy bills and fewer repairs add up.

Balancing cost and durability is wise. A sturdy cooler lasts longer. It handles daily demands better. Investing upfront prevents future headaches.

Create Refrigeration: Your Trusted Partner in Cold Chain Solutions

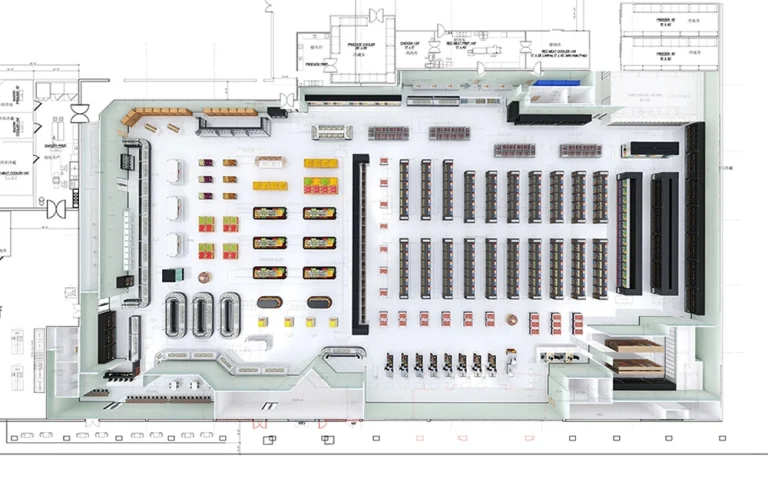

SHANDONG CREATE REFRIGERATION CO., LTD. is based in Xingfu Industrial Park, Binzhou City, Shandong Province, China. Its products meet global standards. They achieve top energy efficiency ratings. This ensures reliable performance and safe food storage. The company offers complete CO₂ solutions, from design to production.

For 16 years, Create Refrigeration has grown. It now includes 12 subsidiaries. It’s a leading one-stop manufacturer in China. The company covers 360,000 square meters. Its products sell well in North and South America, Southeast Asia, and Europe.

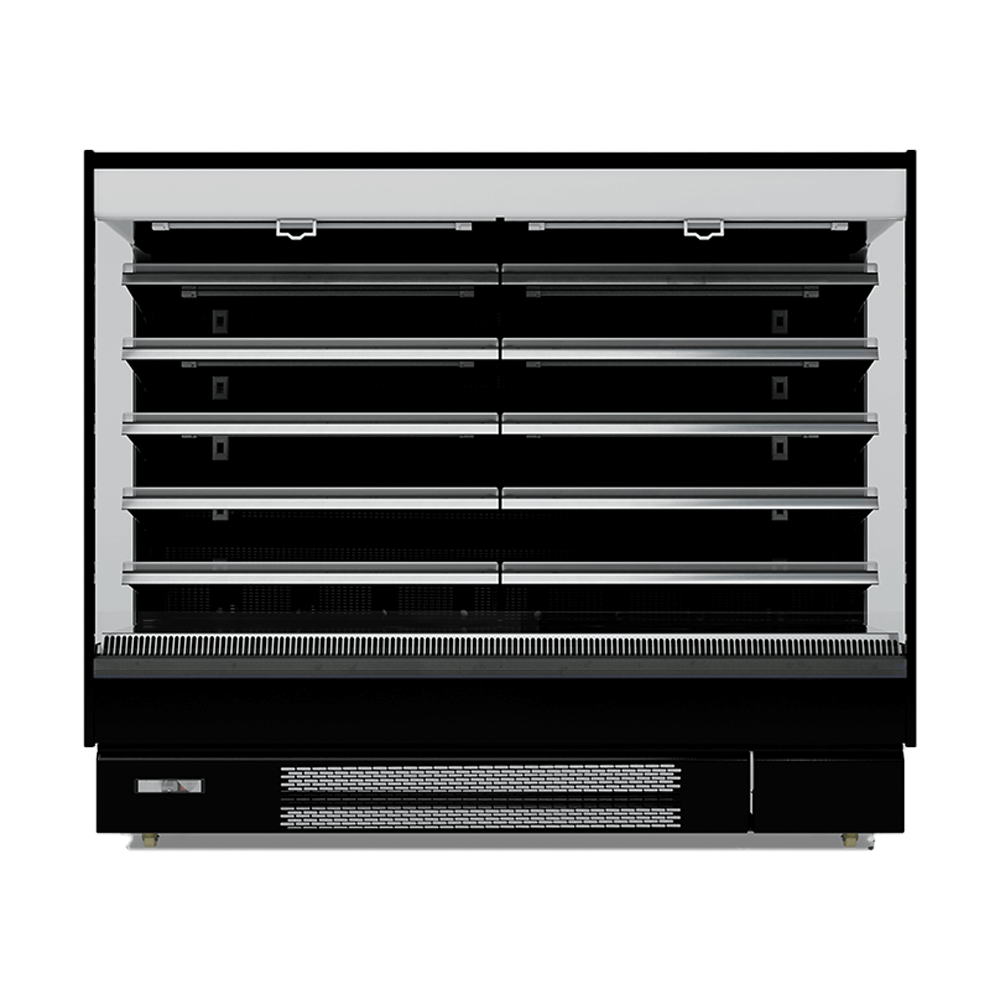

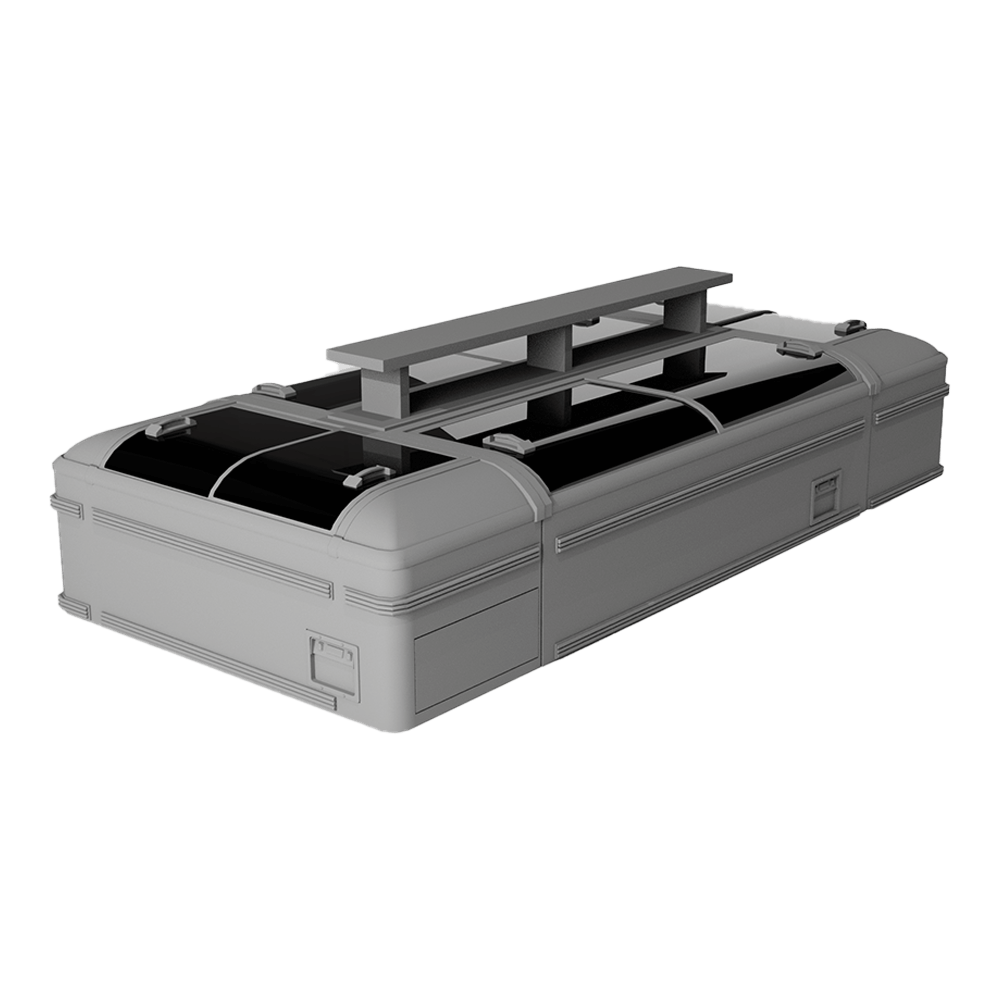

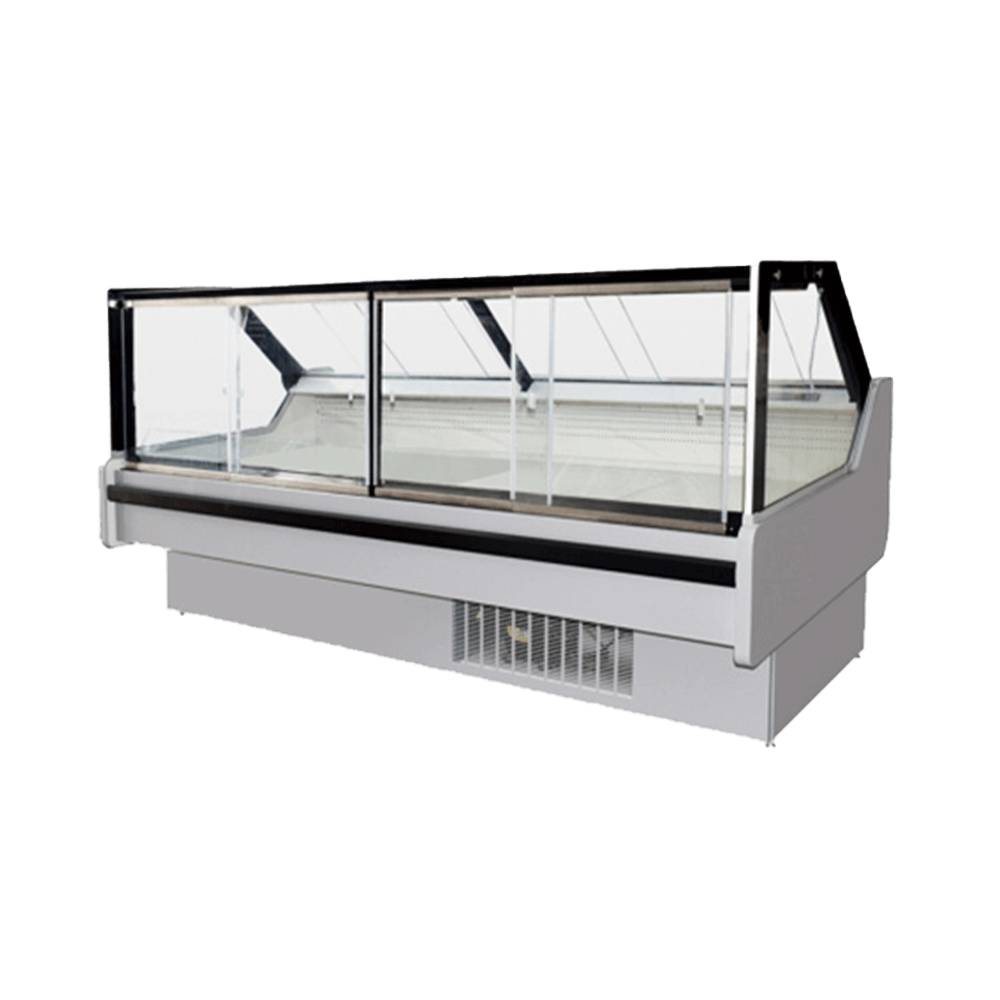

Create Refrigeration focuses on commercial supermarket equipment. It builds walk-in coolers, freezers, and display cases. These include air curtain cabinets and island freezers. Each suits specific business needs. The company prioritizes safe, energy-saving, and eco-friendly practices. It uses R290 refrigerant. Its systems ensure low-energy operation. Stable air curtains and efficient cooling save power.

Summary of Key Differences Between Indoor and Outdoor Installations

Indoor and outdoor walk-in coolers differ in several ways. Structurally, insulation and materials vary. Outdoor units need thicker insulation and tougher panels. Mechanically, compressor placement differs. Outdoor units keep compressors close for access. Environmentally, weatherproofing is critical for outdoor models. Ventilation and drainage needs also vary. Financially, outdoor units cost more initially. They may also face higher repair costs.

Choosing the right cooler requires planning. Assess your space and needs. Consider long-term costs. A professional evaluation helps. It ensures the best fit for your goals.

FAQs

Q1: What’s better for my restaurant—an indoor or outdoor walk-in cooler?

A: It depends on space and weather. Indoor units suit limited outdoor areas. They need stable environments. Outdoor units work if exterior space is secure and weather isn’t extreme. Proper weatherproofing is essential.

Q2: Are outdoor walk-in coolers safe during extreme weather?

A: Yes, they’re built for tough conditions. Features like sun-resistant panels, heated drains, and sealed electrical parts ensure safety. Proper design handles harsh weather effectively.

Q3: Does Create Refrigeration offer custom-sized walk-in coolers?

A: Yes. Create Refrigeration supports custom orders. You can add your logo. They also provide free CAD drawings and 3D renderings. This helps visualize your solution.