In every cooling system, the refrigeration evaporator is a key part. It does the main job in the cooling process. This device takes in heat from the area or thing being cooled. Then, it passes that heat to the refrigerant. How well the system works, saves energy, and lasts depends a lot on the evaporator’s design and shape.

Picking the right evaporator is important for saving power and getting good cooling. Whether you’re setting up a store’s coolers or improving a big storage space, knowing your choices helps you choose wisely for your needs.

Top 5 Types of Refrigeration Evaporators

In 2025, the industry uses several main kinds of evaporators. Each fits different jobs. Today’s systems often use green refrigerants like R290 (propane) and CO₂. This helps the planet by following global eco-friendly goals.

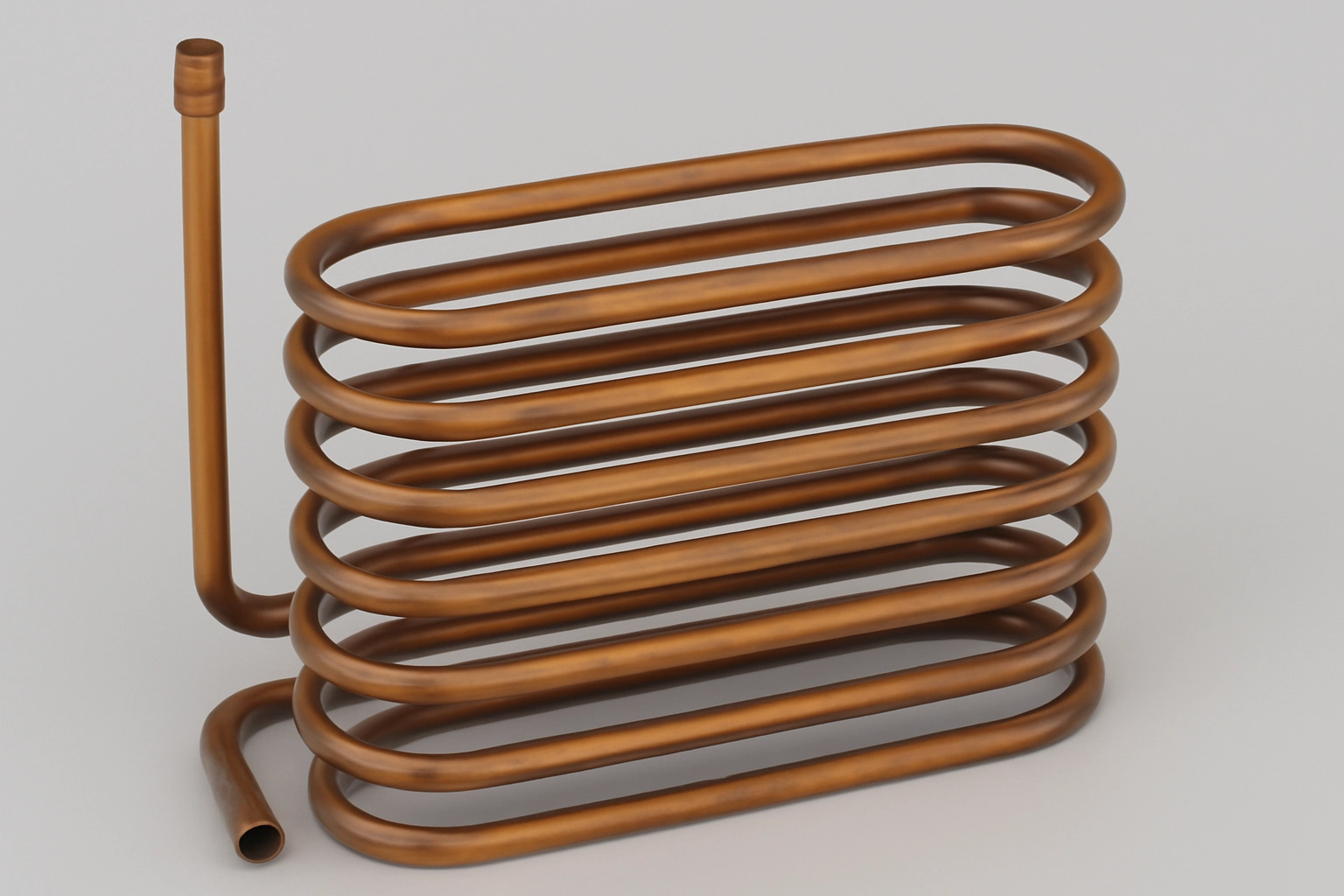

Bare Tube Evaporators

This is the easiest kind. It uses plain metal tubes, often made of copper or steel. The refrigerant moves inside these tubes. Air or liquid flows over the tubes to swap heat.

- Best For: Places where keeping things simple and clean is important. Think of big freezers or tanks that cool liquids.

- Pros & Cons: These are tough and cheap. But, they have a small area for heat swapping, so they’re not as good at cooling as other kinds.

Bare tube evaporators are great for basic setups. Their simple design makes them easy to clean. This is helpful in places like walk-in freezers, where dirt can build up fast. However, their small surface means they don’t cool as quickly or strongly as others. You might need a bigger system to get the same cooling power.

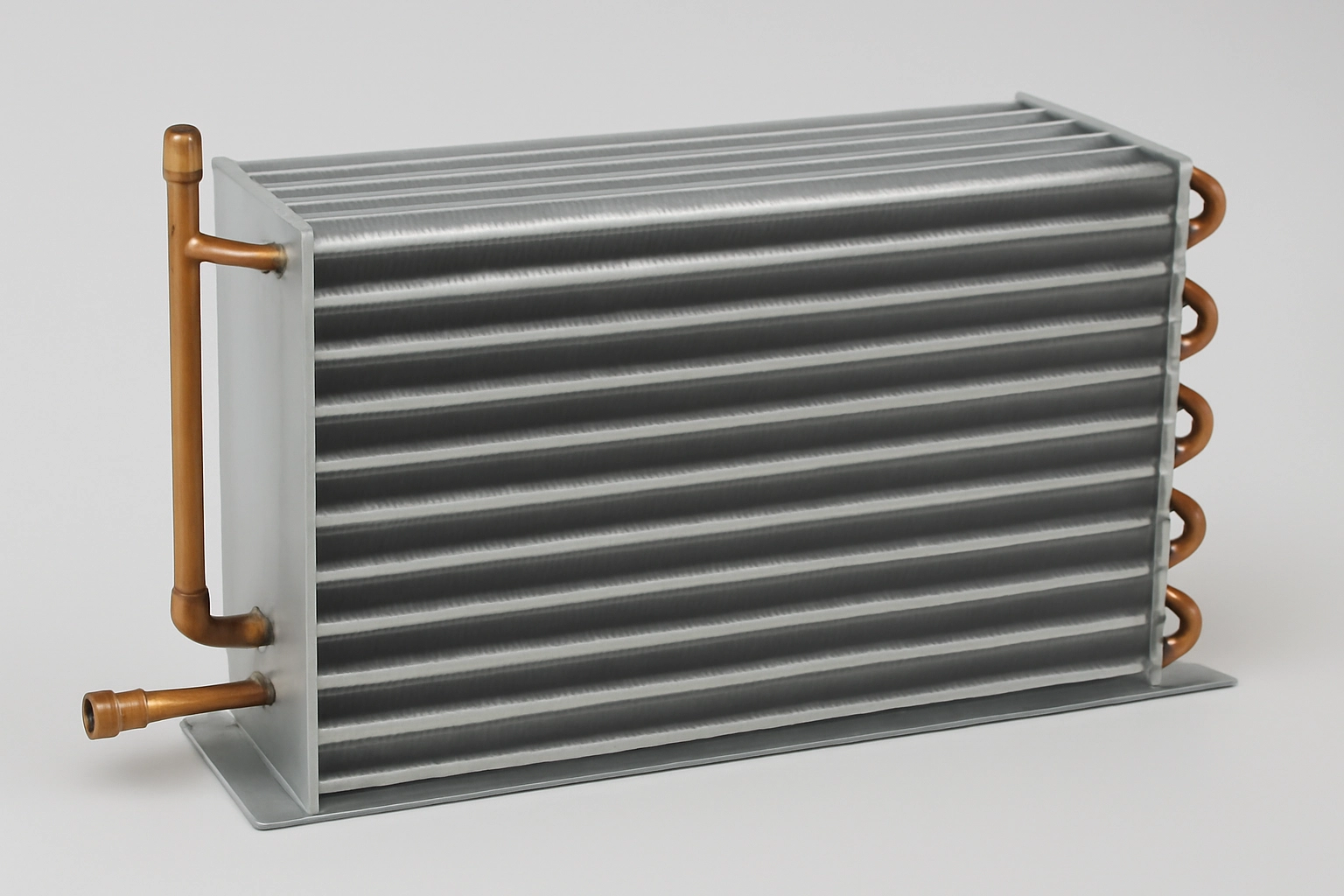

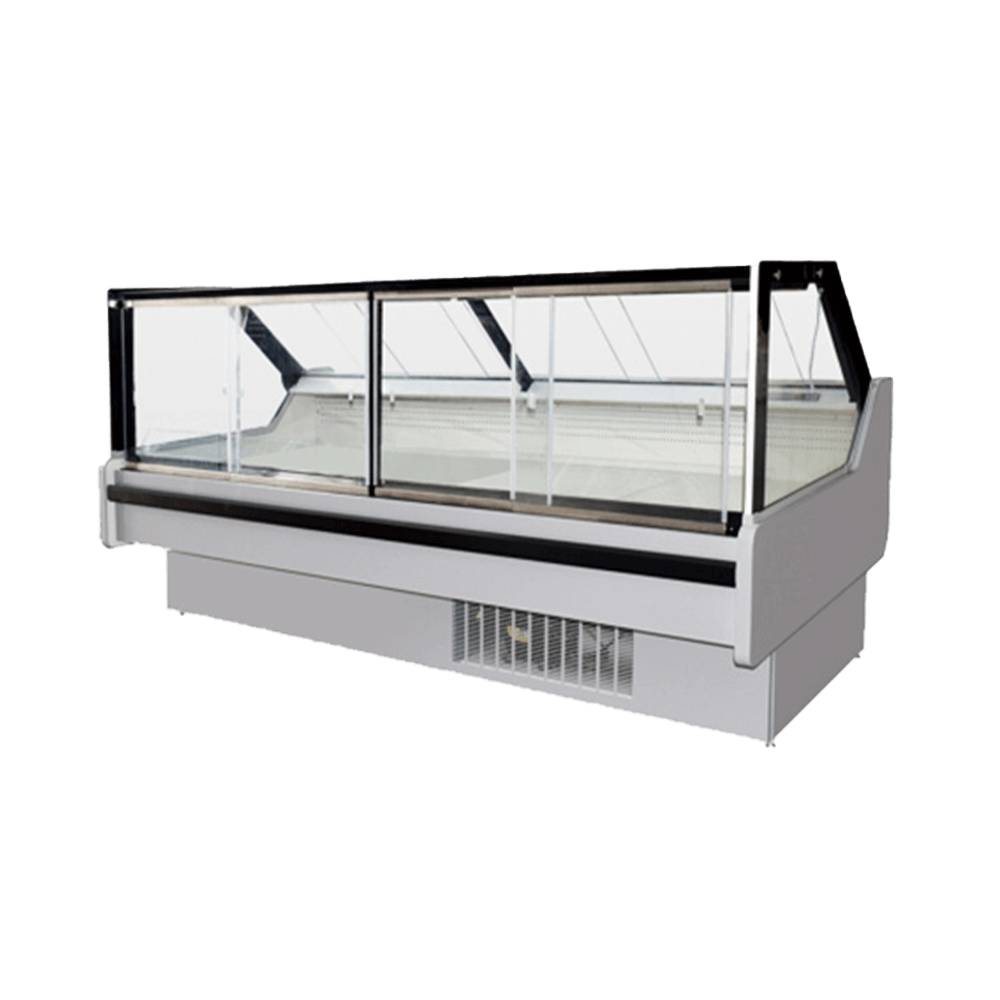

Finned Tube Evaporators

This kind builds on the bare tube idea. It adds thin metal fins to the outside of the tubes. These fins make the heat-swapping area much bigger. This makes cooling much better.

- Best For: Lots of store cooling systems, like small coolers, display cases, and walk-in fridges, where you need strong cooling in a small space.

- Pros & Cons: They cool well and work in many places. But, the fins can get dirty with dust or bits of stuff. You need to clean them often to keep them working right.

Finned tube evaporators are popular because they’re so good at cooling. The fins help move heat faster, which saves energy. They fit well in tight spaces, like store display cases. But, if dirt piles up on the fins, the system won’t cool as well. Regular cleaning keeps them in top shape.

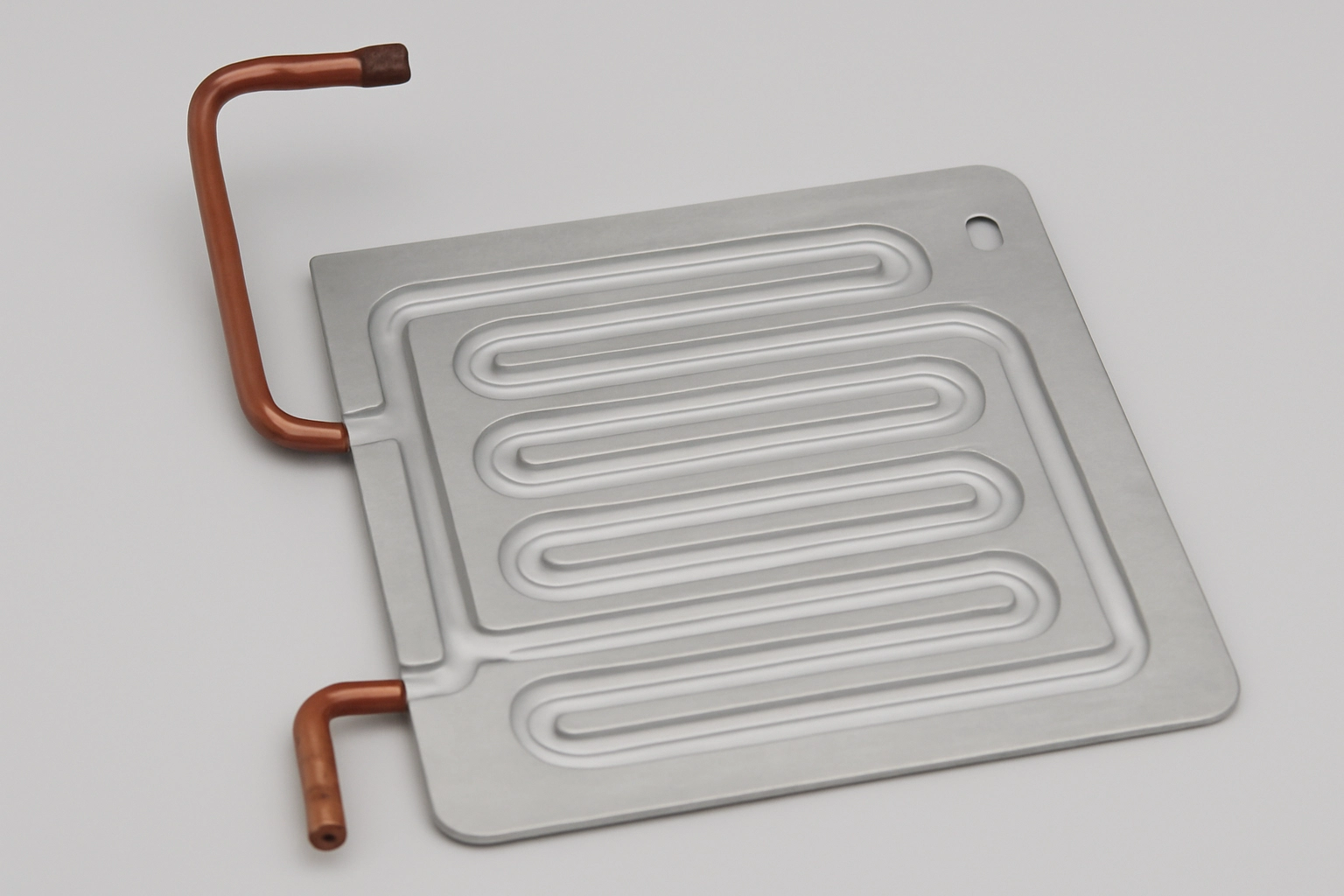

Plate Type Evaporators

Plate evaporators use metal plates stuck together. These plates make paths for the refrigerant to flow through. Their flat, small shape gives a big heat-swapping area in a tiny space.

- Best For: Small or movable units where space is tight. Examples include under-counter freezers, ice cream machines, and tiny fridges.

- Pros & Cons: They save space and don’t need much care because they’re sealed. This makes them great for small setups.

These evaporators are perfect for small machines. Their design fits right into the walls of things like mini-fridges. Since they’re sealed, they don’t get as dirty as other kinds. This means less work to keep them running. They’re a smart choice when you don’t have much room.

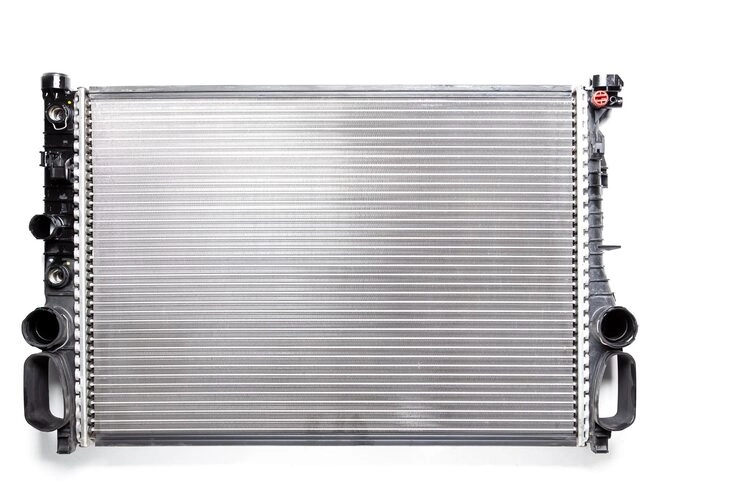

Shell and Tube Evaporators

This big, strong design has many small tubes inside a large round shell. The refrigerant usually flows through the small tubes. The liquid to be cooled, like water or brine, moves around in the outer shell.

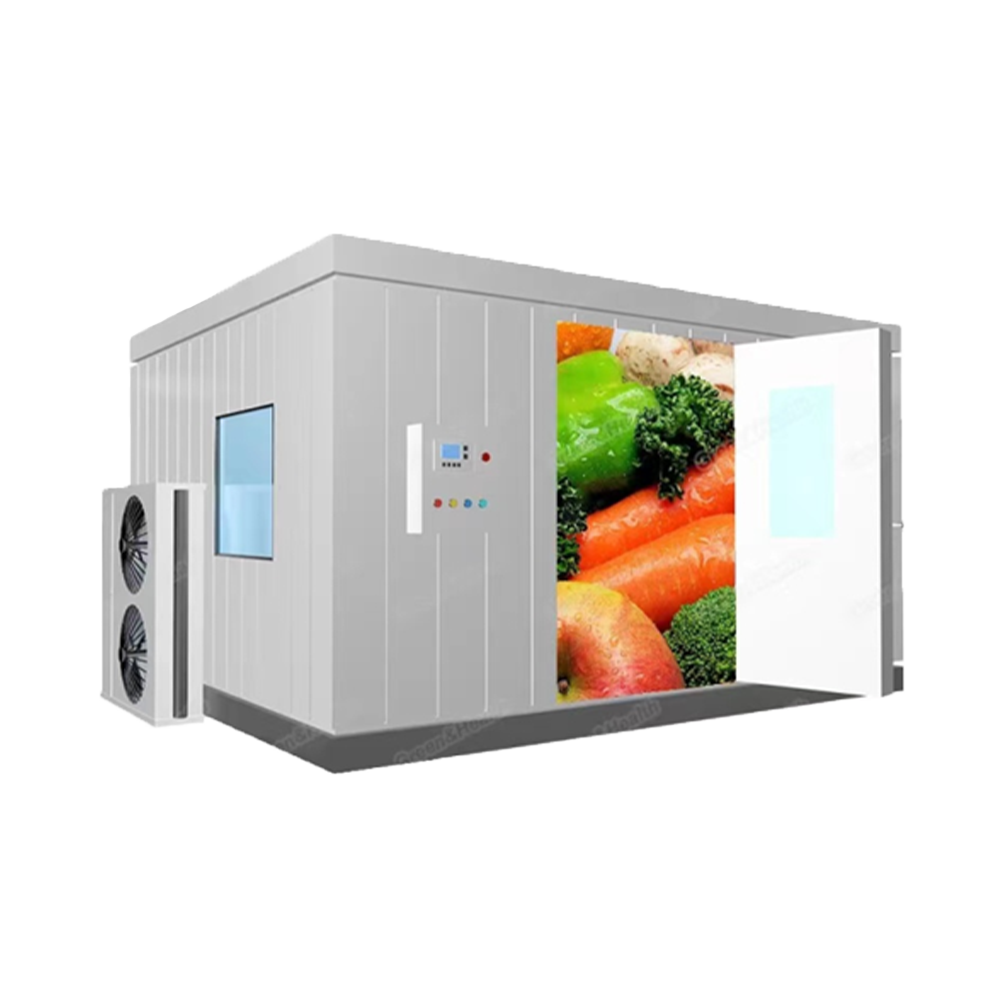

- Best For: Huge industrial jobs, like food factories, big cold storage rooms, or systems that cool liquids.

- Pros & Cons: They’re very strong and can handle big cooling tasks and high pressure. But, they’re complicated. They might need special care, like cleaning out scale buildup.

Shell and tube evaporators are built for heavy work. They can cool large amounts at once, which makes them great for factories. Their tough design handles tough conditions. But, they’re not simple. You might need experts to fix or clean them, especially if minerals build up inside.

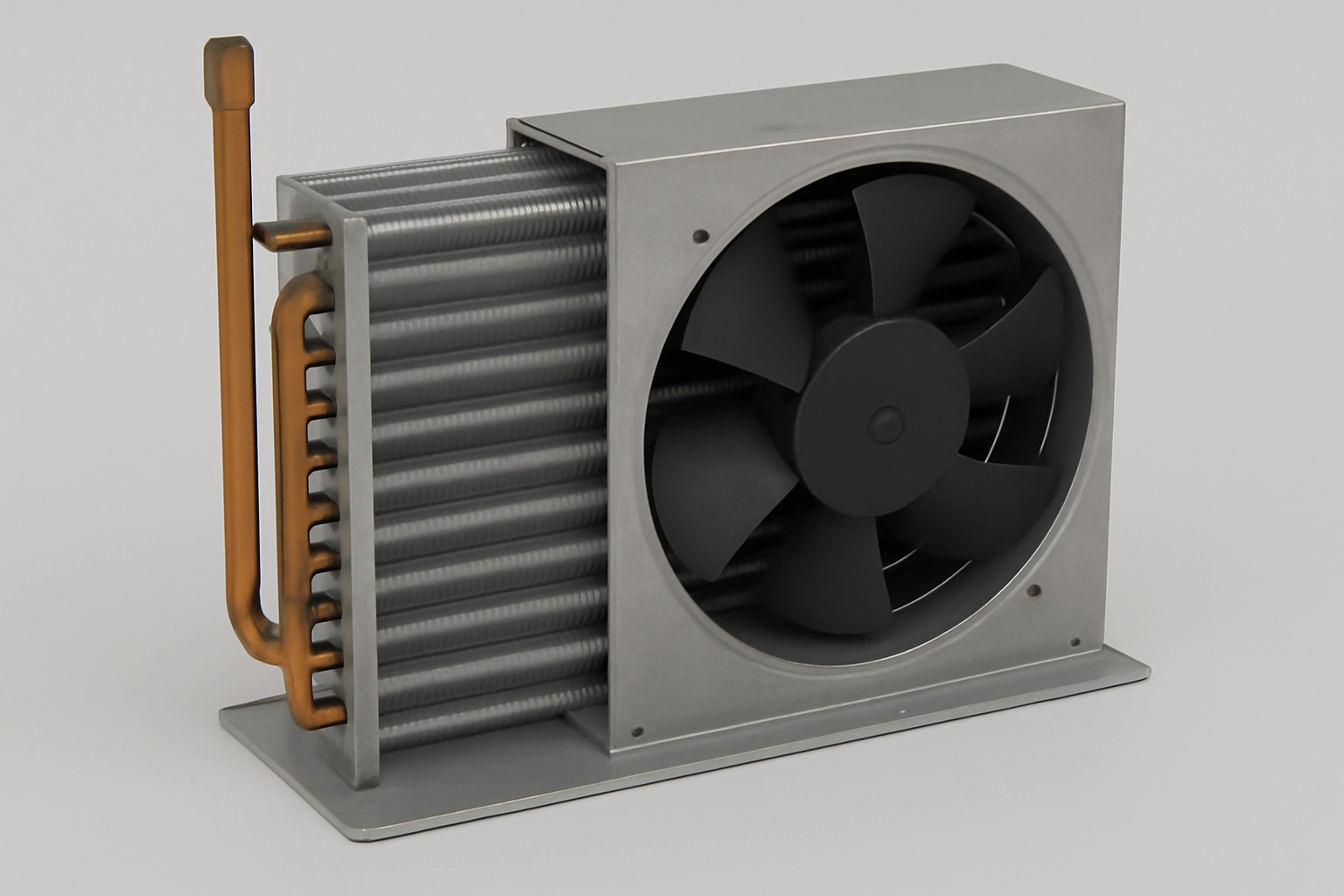

Forced Convection (Fan Coil) Evaporators

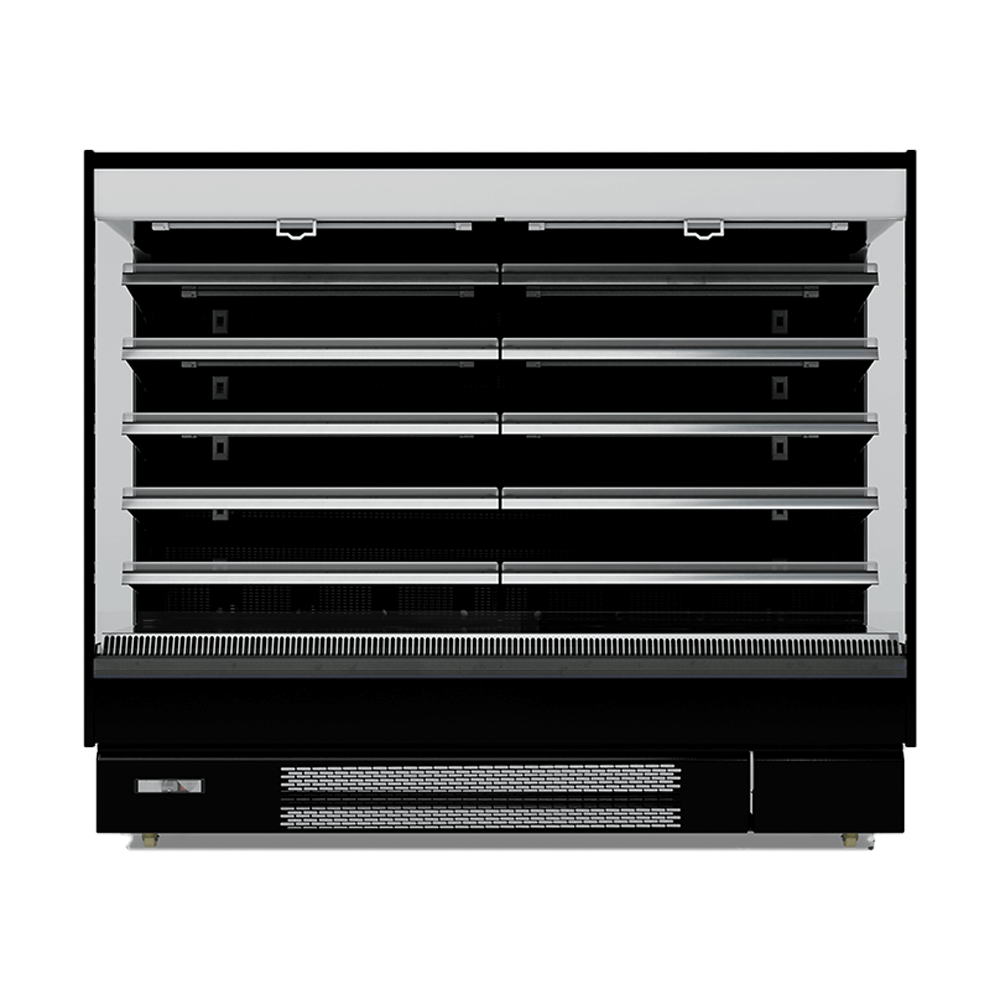

These aren’t a separate kind but an upgrade, usually to finned tube evaporators. They have fans that push air over the evaporator coil. This makes heat swapping faster and keeps cooling even.

- Best For: Systems needing steady temperatures and fast cooling. Think of open-front display coolers, frozen food areas, or drink fridges.

- Pros & Cons: They give great, even cooling. But, the fans and motors add parts that need checking and might need replacing.

Fans make these evaporators super effective. They cool things down quickly and keep the temperature steady. This is great for stores where food needs to stay cold all the time. But, the fans can break or wear out, so you need to check them often.

Common Problems with Refrigeration Evaporators and How to Avoid Them

Keeping evaporators in good shape is a must to avoid problems that hurt how they work.

- Ice Build-Up on Coils: This happens if the defrost system breaks, air can’t flow well, or there’s too much wet air. Ice covers the coils like a blanket. This makes cooling weak and puts stress on the compressor. Solution: Check defrost timers and heaters often. Make sure fans and vents are clear. Keep door seals tight to control wet air.

- Weak Cooling: Dirt or grease on coils can block heat swapping. A refrigerant leak can lower pressure in the system. Both make cooling bad. Solution: Clean coils on a schedule. Check for leaks regularly to find problems early.

- Rust and Leaks: Water or chemicals can make tubes rust over time. This can cause refrigerant to leak out. Solution: Make sure water drains well. Use evaporators made of rust-proof materials, especially in wet or tough places.

- Fan Motor Problems: In fan systems, a bad motor can make temperatures uneven or cause weird noises. This can overheat the compressor. Solution: Look at fan motors often. Swap out broken ones fast to avoid bigger issues.

The Create Refrigeration Advantage: Engineered for Reliability

Understanding these issues is one thing. Picking equipment made to avoid them is another. For 16 years, Create Refrigeration has made commercial freezer and cooler. They use smart technology to make sure their products work well and last long.

Their solutions fix common evaporator problems:

- Advanced Forced Convection Systems: Their island cabinets and display fridges use high-quality copper tube evaporators with top EBM fans. This setup cools things fast and evenly. It cuts down on cold spots.

- Smart Auto-Defrost: To stop ice buildup, their systems have automatic defrost cycles. These keep coils clean for better cooling. They also give more space inside and make freezing work better.

- Power Saving: They use frequency conversion technology in compressors. This can cut power use by over 55%. It also reduces wear on the compressor.

- Strong, Lasting Materials: They use rust-proof copper tubing and tough construction. This makes equipment last longer and gives better value for your money.

As one of China’s biggest one-stop manufacturers, they work worldwide. They offer full OEM/ODM services, from CAD designs to final setup. Their products have CE, ETL, and UL certifications.

Conclusion

From plain bare tubes to high-tech fan-coil systems, the evaporator is the heart of good cooling. Regular care stops common problems. But, success starts with picking top-quality equipment. Choosing a trusted maker like Create Refrigeration, with smart designs and global know-how, sets up any cooling system for success.

FAQs

Q1: What is the most energy-efficient type of refrigeration evaporator?

A: Forced convection (fan coil) evaporators are usually the best for saving power in stores. Their fans move heat fast and evenly, so the compressor works less. Create Refrigeration adds things like variable-speed fans and frequency conversion technology. These can cut power costs by over 55%.

Q2: How do I know if my refrigeration system’s evaporator needs attention?

A: Watch for uneven temperatures, frost or ice on coils, odd noises from fan areas, or bigger power bills. These signs mean it’s time to check or fix the system.

Q3: Can I get refrigeration equipment customized for my store’s specific layout?

A: Yes, top makers offer lots of custom options. For example, Create Refrigeration makes 3D layout designs, adjusts cold storage sizes, and offers modular cabinets to fit a store’s unique needs perfectly.