Keeping food and other items fresh is super important for businesses, from tiny shops to huge factories. At Shandong Create Refrigeration Co., Ltd., we know how vital good refrigeration is for your work. Whether you run a grocery store, a restaurant, or a big storage place, picking the right cooling system helps keep your products fresh and your business running smoothly. In this article, we’ll look at the main differences between commercial refrigerators and industrial cooling systems to help you choose what’s best for you.

Overview of Commercial and Industrial Refrigeration Systems

To pick the right cooling system, you need to know what makes commercial and industrial systems different. Each is made for specific jobs, sizes, and needs, which affect how they work and what they’re used for.

Defining Commercial Refrigeration Systems

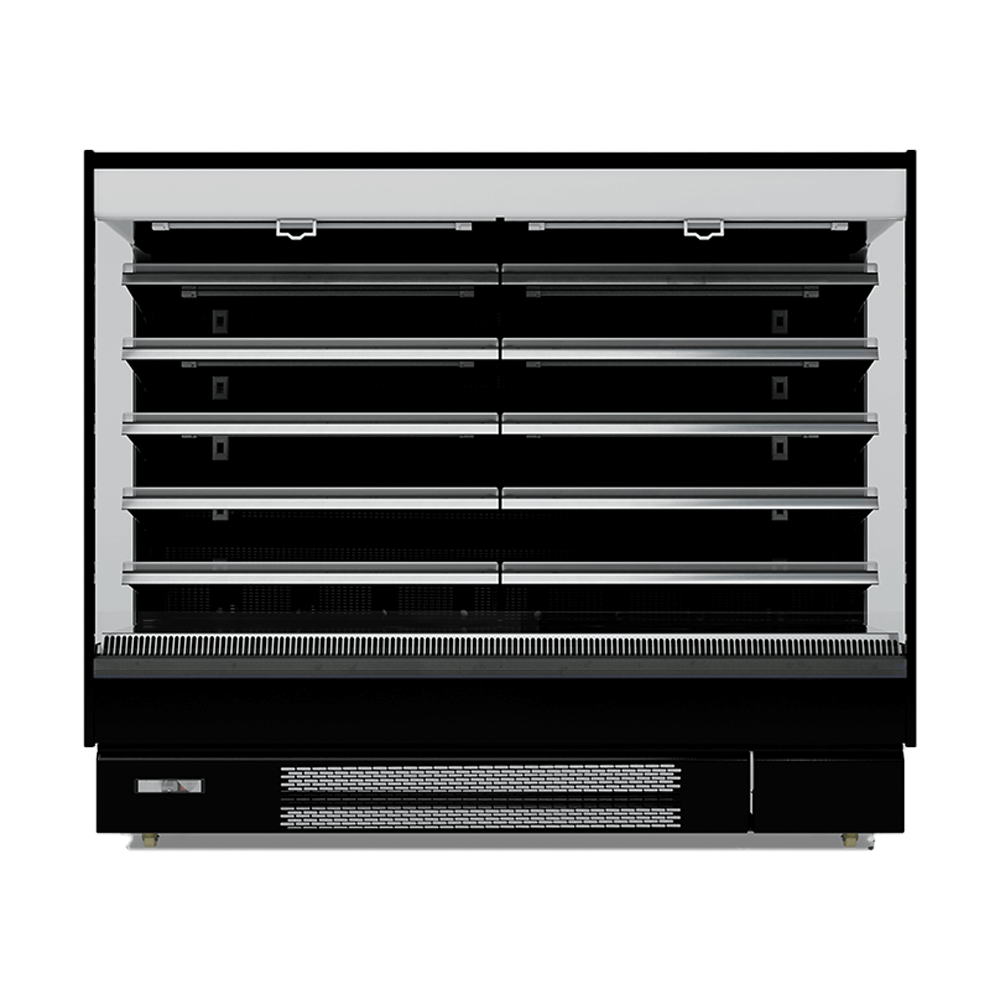

Commercial refrigeration systems are built for businesses that need steady cooling to keep food, drinks, or other items fresh in stores or restaurants. You’ll see them in supermarkets, small shops, cafes, or diners. At Create Refrigeration, our commercial refrigerators, like the 4-Door Commercial Upright Showcase, are designed to look nice, work well, and save energy. They keep your products fresh and make shopping fun for customers.

Defining Industrial Refrigeration Systems

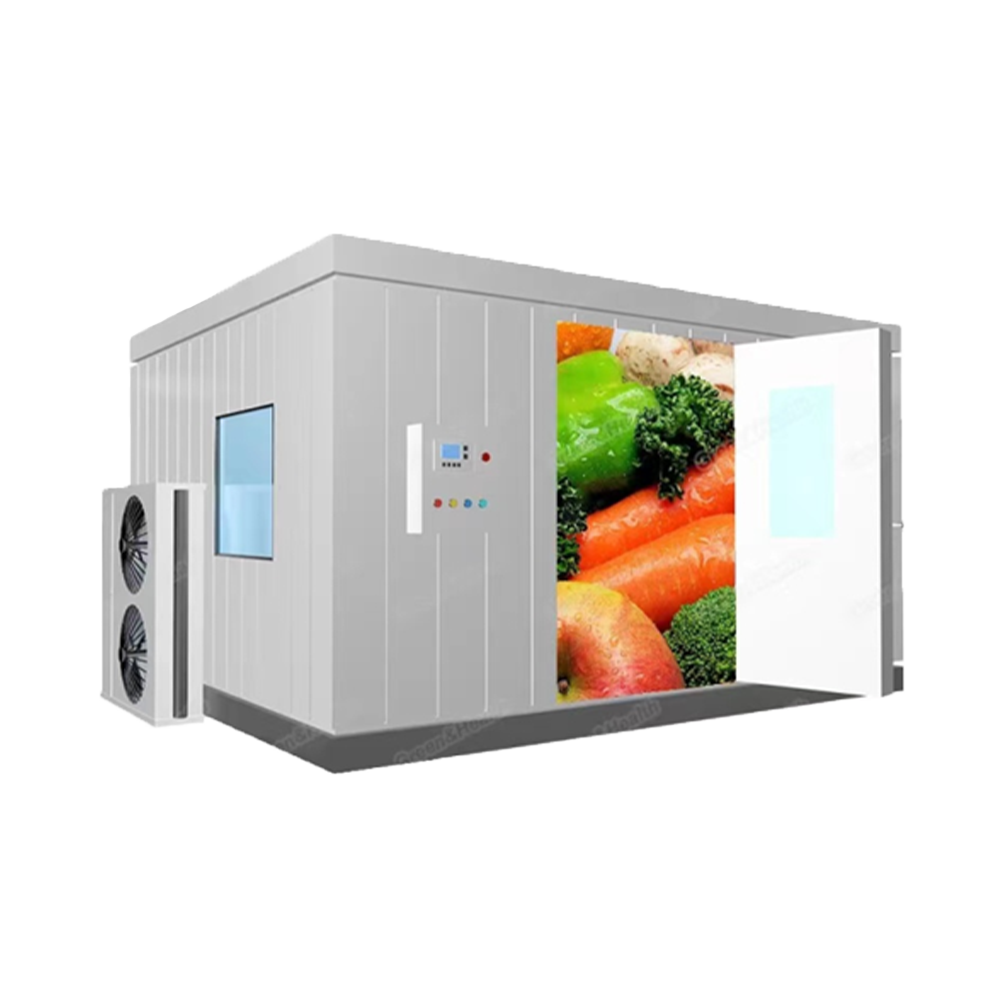

Industrial refrigeration systems are made for big jobs that need strong cooling. These are used in storage warehouses, food factories, or big cooling facilities. They’re built to handle tons of items, keep temperatures exact, and work in tough settings. They often use special cooling liquids like ammonia or CO2 to work better.

The difference between these systems comes from their size, complexity, and purpose. Let’s check out how they’re used in different places.

Applications of Commercial vs. Industrial Refrigeration

Commercial and industrial cooling systems are used in very different ways because of how they’re built and what they can do. Knowing where each one shines helps you pick the right one for your business.

Common Uses of Commercial Refrigeration

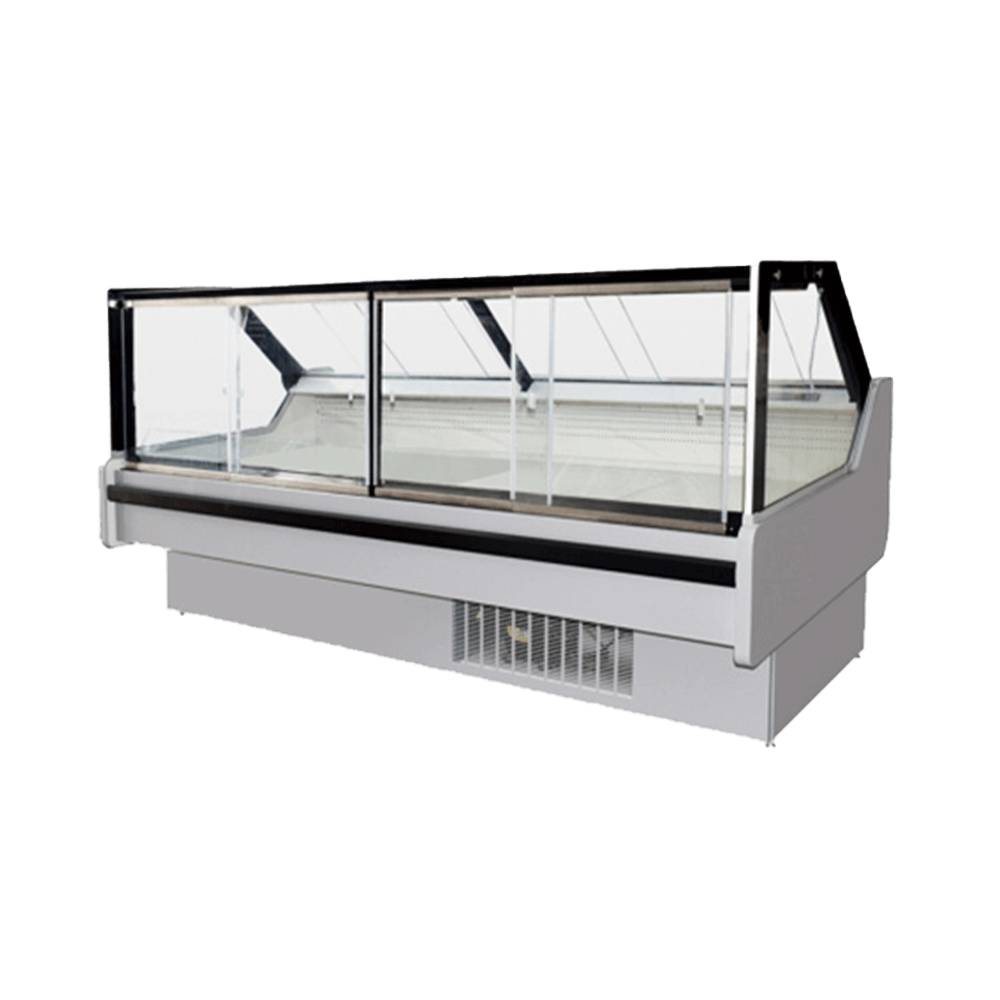

Commercial refrigeration is perfect for stores and food places where easy access and good looks matter. Here are some common uses:

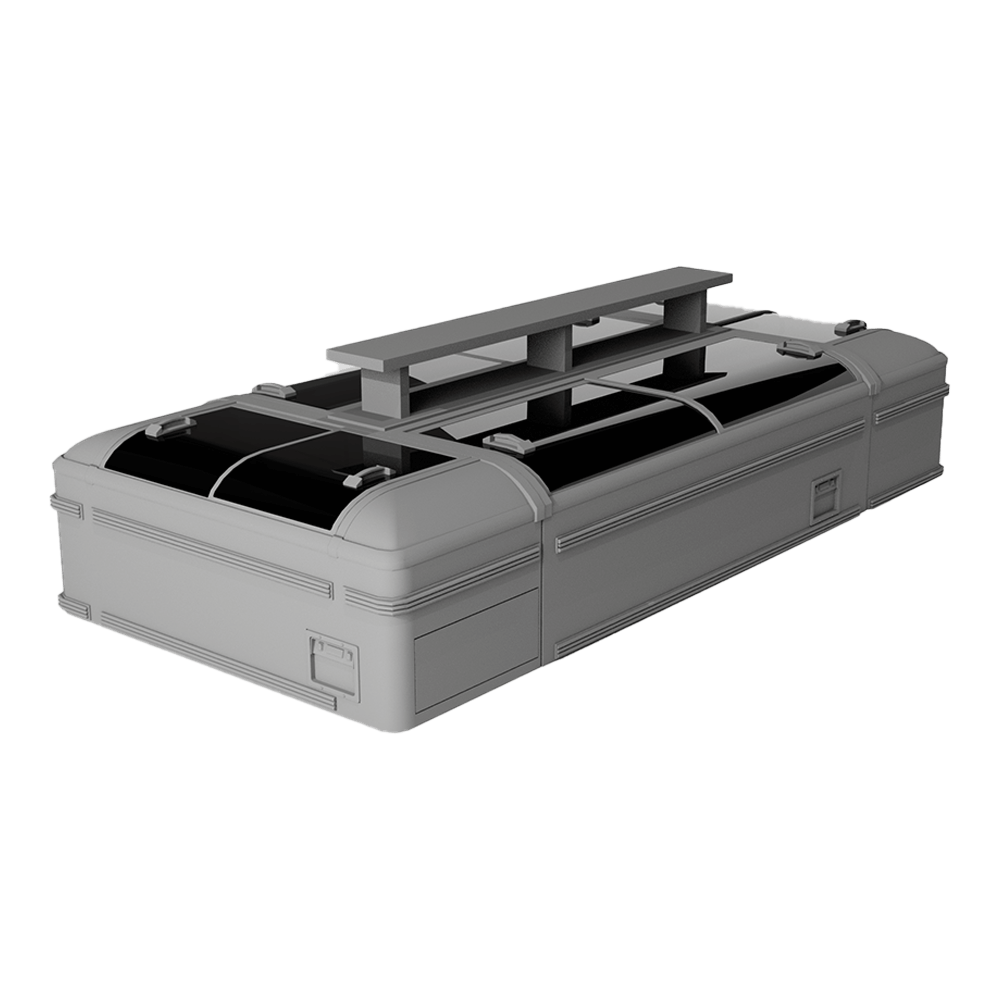

- Supermarkets and Grocery Stores: Showing fresh veggies, milk, or drinks in units like our Supermarket Combined Island Freezerfor frozen fish, meat, and ice cream.

- Restaurants and Cafes: Keeping ingredients and ready foods at the right temperature for quick use.

- Small Shops: Displaying drinks and snacks in cool, small units.

- Flower Shops and Drugstores: Keeping flowers or medicines at the right temperature.

These systems focus on easy-to-use designs and energy-saving features to meet the daily needs of smaller businesses.

Typical Applications of Industrial Refrigeration

Industrial cooling systems are built for heavy work that needs big-time cooling. Common uses include:

- Storage Warehouses: Holding lots of fresh or frozen goods, like frozen fish, meat, or ice cream, for shipping.

- Food Factories: Keeping things cold while making products like meat or milk.

- Medicine Factories: Controlling temperatures for sensitive items.

- Chemical Plants: Cooling processes that get really hot or use tricky materials.

Moving from commercial to industrial uses shows the need for systems that handle bigger loads and tougher jobs. Next, we’ll look at how size and capacity set them apart.

Size and Capacity Differences

The size of a cooling system matters a lot when deciding what’s right for your business. Commercial and industrial systems are very different in size and how much they can cool.

Scale of Commercial Refrigeration Units

Commercial units are usually smaller and fit in places with less space. For example, our 4-Door Commercial Upright Showcase is small but holds plenty of drinks and fresh items, making it great for stores. These are often plug-in units that hold a few hundred to a few thousand liters, enough for daily store or restaurant needs.

Capacity Requirements for Industrial Refrigeration Systems

Industrial cooling systems are made for huge jobs. They can cool whole warehouses or big factories, with capacities that handle tens of thousands of liters. These systems are custom-made to meet special needs, like keeping things super cold for frozen goods or running all the time in busy places.

The size and capacity differences lead to different designs and builds, which we’ll talk about next.

Design and Construction Variations

How cooling systems are built shows what they’re meant to do. Commercial units focus on being easy to use and looking good, while industrial systems are all about being strong and working hard.

Structural Characteristics of Commercial Refrigerators

Commercial refrigerators, like the ones we make at Create Refrigeration, are built to be handy and nice-looking. Here are some key features:

- Glass Doors and Displays: Let customers see products clearly, like in our 4-Door Commercial Upright Showcase.

- Small Size: Fits in stores without taking up too much space.

- Stainless Steel Surfaces: Tough and easy to clean in busy places.

- Movable Shelves: Let you change the setup for different products.

These features make commercial units perfect for places where customers shop.

Engineering Features in Industrial Refrigeration Systems

Industrial systems are built to be tough and work well. Key features include:

- Strong Materials: Handle rough conditions and constant use.

- Big Pipes and Motors: Support large cooling jobs with special liquids like ammonia or CO2.

- Flexible Designs: Can be changed or made bigger for different needs.

- Smart Controls: Keep temperatures and humidity just right.

These build differences affect how much energy they use, which we’ll cover next.

Energy Efficiency and Power Consumption

Saving energy is important for both commercial and industrial cooling systems, but they use power in different ways.

Energy Efficiency Standards in Commercial Units

Commercial refrigerators are made to save energy while working well. Our units at Create Refrigeration use things like LED lights, strong motors, and green cooling liquids (like R290) to use less power while keeping drinks or frozen foods cold.

Power Demands of Industrial Refrigeration Systems

Industrial systems need a lot more power because they’re so big and run all the time. They use smart tools like speed-changing motors to save energy, but they still use a lot because they cool huge spaces or keep things super cold for frozen meat or ice cream.

Maintenance needs are also different because of how complex each system is.

Maintenance and Operational Requirements

Taking care of your cooling system keeps it working well for a long time. But commercial and industrial systems need different kinds of care.

Maintenance Needs for Commercial Refrigerators

Commercial units need regular, simple care, like:

- Cleaning cooling parts to stop dust from building up.

- Checking cooling liquid levels and looking for leaks.

- Setting temperature controls to keep things just right.

- Oiling motors to keep them running smoothly.

Our team at Create Refrigeration helps keep your units in top shape. For help, contact us.

Operational Challenges in Industrial Systems

Industrial systems have tougher maintenance needs because they’re bigger and always running. These include:

- Checking big pipes for leaks or pressure problems.

- Looking at large motors and control systems often.

- Handling lots of cooling liquid, which needs special care.

- Planning maintenance without stopping work.

These challenges affect how much each system costs, which we’ll look at next.

Cost Implications and Investment Considerations

Cost is a big deal when choosing between commercial and industrial cooling systems. Each has different money impacts.

Pricing Factors for Commercial Refrigeration Systems

Commercial units are usually cheaper. Costs depend on:

- Size and Features: Glass doors or fancy displays cost more.

- Energy Savings: Green units cost more at first but save money later.

- Warranty and Help: Our commercial refrigerators come with a one-year warranty on the unit and three years on main parts, which adds value.

Cost Analysis for Industrial Refrigeration Solutions

Industrial systems cost more at the start because of:

- Custom Builds: Made special for certain jobs, which raises the price.

- Hard Setup: Big systems need pro installation and extra setup.

- Care Costs: Keeping complex systems running can cost a lot.

Knowing these costs helps businesses plan for the long run.

Temperature Range

Temperature needs also set commercial and industrial systems apart:

| System Type | Temperature Range | Typical Uses |

| Commercial Refrigeration | 0°C to 10°C (refrigerators) -18°C to -22°C (freezers) |

Drinks, milk, frozen fish, meat, ice cream |

| Industrial Refrigeration | -40°C to 10°C | Storage, food factories, medicines |

Commercial units keep standard temperatures for stores. Industrial systems can go super cold for special needs.

Create Refrigeration: A Trusted Supplier for Commercial Refrigerators

At Create Refrigeration, we’re proud to be a top provider of great commercial refrigeration solutions. With 25 years in the business, our 50,000-square-meter factory makes over 23,000 units a year, serving customers in more than 70 countries.

Commitment to Quality and Reliability

We follow strict rules like ROHS, CE, and ISO 9001 to make sure our products are safe, green, and energy-saving. Our one-year warranty on plug-in refrigerators and three-year warranty on main parts show we trust our products to work well.

Product Range and Customization Options

We offer lots of products, like the Supermarket Combined Island Freezer for frozen foods and the 4-Door Commercial Upright Showcase for drinks. We also make custom solutions, giving you drawings and 3D models to fit your needs perfectly.

Conclusion

Picking between commercial and industrial cooling systems depends on your business size, needs, and budget. Commercial refrigerators, like ours at Create Refrigeration, are great for stores and restaurants, offering energy-saving, easy-to-use options. Industrial systems work best for big storage or factories that need strong, high-capacity cooling. By understanding these differences, you can choose a system that helps your business run better and reach its goals.

FAQs

Q1 What is the primary distinction between commercial and industrial refrigeration systems?

A1 The main difference is their size and use. Commercial refrigeration systems are for stores and restaurants, giving small, easy-to-use units for smaller needs. Industrial systems are for big places like warehouses or factories, offering strong cooling for heavy jobs.

Q2 Are industrial refrigeration systems more expensive than commercial ones?

A2 Yes, industrial systems cost more because they’re bigger, custom-made, and harder to set up. Commercial units, like ours at Create Refrigeration, are cheaper and made for regular store needs.

Q3 How do I determine which refrigeration system is suitable for my needs?

A3 Look at your business size, storage needs, and budget. For stores or restaurants, a commercial unit like our 4-Door Upright Showcase is great. For big storage or factories, an industrial system is better. Reach out to our team at Create Refrigeration for custom advice and solutions.