Supermarket freezers are not just big versions of home appliances. They serve as vital parts of business operations. These units get built to run without stops in busy stores. Unlike home freezers, they handle steady workloads. They keep tight temperature ranges for different kinds of foods. Plus, they follow changing rules on the environment and food safety. All this detail leads to higher prices.

Freezers for shops focus on strong performance, long-lasting build, and meeting tough food safety rules. These setups work around the clock. They often face tough conditions in stores. So, builders aim for dependable work, lower power use, and flexible setups. The price tags show more than just their large size. They cover smart building work, needed approvals, and special tweaks to fit various store types. Now, let’s look at the main reasons why these freezer setups cost so much to buy.

Why Does Engineering Complexity Drive Up Freezer Costs?

First sight, but it holds much more detail. These setups frequently use several compressors that operate together. This provides backup options. It also helps keep the right temperatures even if one part fails a bit. Such features make sure work never stops. In food shops, any pause can cause food to go bad. Therefore, this stays key for daily business. Builders now often add variable speed inverter compressors to cut down on power needs. These parts adjust their speed based on how much cooling the system requires at the moment. As a result, they boost overall efficiency. At the same time, they lessen damage from constant use.

On top of that, plenty of these freezers connect to bigger central refrigeration networks. Fitting them in calls for careful work between machine experts and control specialists. The steps of planning, building, and starting up all push the total expenses higher. In fact, this teamwork ensures smooth runs but adds to the upfront spend.

How Do Material Choices and Structural Design Add to Expense?

Freezers in supermarkets deal with lots of people walking by. They also face doors opening and closing often. Yet, they must hold steady inside temperatures. To manage this, makers pick top-quality materials. Strong stainless steel and parts that resist rust boost how long they last. However, these choices raise the cost of raw supplies.

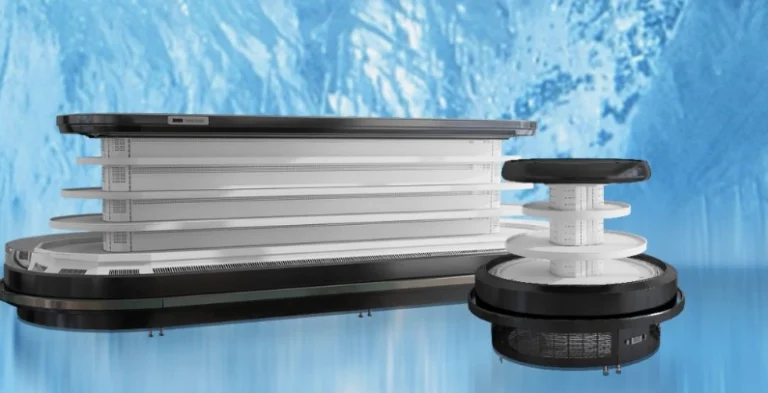

Another big part comes from insulation. The walls need to block heat well to limit warmth getting in. This helps with better power savings. Triple-pane glass doors with coatings against fog offer clear views. They stop water drops from forming too. Such choices make building harder and more costly. Overall, these steps lead to reliable units that perform under pressure. You can check out samples of these strong units, like the Glass Door Freezer & Chiller from Create Refrigeration. It works well for frozen items such as ice cream or meat. It also suits chilled goods like drinks or fresh fruits.

What Certifications Are Required—and Why Are They Expensive?

Equipment for business refrigeration follows firm global rules. Units have to match HACCP guidelines. These ensure safe food handling in different temperature areas. Compliance here protects customers and avoids legal issues. Besides that, new environmental laws limit some cooling gases. So, following EPA SNAP rules or EU F-Gas directives means switching to natural options like R290 or CO₂. These require unique system builds and parts. The shift demands extra engineering to handle them safely and effectively. Gaining ENERGY STAR® or similar approvals costs more because of thorough checks. Often, units include smart ways to defrost, efficient compressors, and LED lights to qualify. These additions not only meet standards but also help in daily savings.

Why Do Lifecycle Costs Influence Initial Investment Decisions?

Freezers in supermarkets run all day and night without breaks. So, running expenses become a huge worry for owners. Weak insulation or slow compressors can spike power bills quickly. That’s why choosing top brands matters. For instance, using the leading inverter compressor in the field makes the unit use less energy. It runs steadily too. In just one year, this can cut electricity costs by up to 50%. Such savings make the higher start price worthwhile in the long run.

Upkeep needs play a role as well in total costs. These systems call for trained experts to fix issues. Any stop in work harms food quality. It also cuts into sales. For these reasons, many shop owners pick tougher, pricier models. They aim to avoid problems and keep business flowing smoothly. In essence, thinking ahead about full ownership costs guides smarter buying choices.

How Do Store-Specific Customizations Affect Pricing?

Shop owners want freezers that fit their exact space needs. This leads to special builds, like stackable or multi-level setups made just for one store. We have a professional design team. We can create a 3D design for your supermarket. We provide you with CAD drawings. And we make 3D renderings to meet all your needs. These services help visualize the final look before building starts.

Brand needs add more layers. Custom colors, built-in lights, or spots for ads require extra steps in making. Such touches improve how shoppers see the store. However, they stretch out production schedules and lift prices. Even so, the tailored approach enhances appeal and fits unique store vibes perfectly.

What Role Does the Global Supply Chain Play in Pricing?

These refrigeration pieces depend on parts like compressors, controls, and sensors from expert makers around the world. Changes in supply lines impact wait times and material prices. Precision assembly requires skilled labor with refrigeration expertise. On top of that, their big size and delicate nature mean high shipping fees. This includes special boxes and climate-safe transport to avoid damage. All these elements in the chain push the final cost up. Yet, they ensure the end product reaches stores in top shape, ready for heavy use.

Create Refrigeration: A Reliable Supplier for Supermarket Freezers

If you need solid commercial cooling options that follow worldwide benchmarks, Create Refrigeration emerges as a top pick. It ranks as China’s biggest all-in-one source for supermarket gear.

Create Refrigeration, as the largest one-stop procurement company for supermarkets and engineering projects in China, is a foreign trade manufacturer that integrates design, production, research and development, and sales. With 25 years of industry experience and an export footprint across 70+ countries, Create offers plug-in and remote refrigeration systems that emphasize energy-saving technology, aesthetic appeal, and compliance with global certifications including CE, ETL, ISO, ROHS, UL, and more. The company focuses on using eco-friendly R290 refrigerants and fresh power-saving materials. It pushes for high efficiency and conservation. In doing so, it promotes a greener way of living. Buyers gain from extra helps like free CAD-based 3D designs and custom space advice. These perks suit shop owners who want to make the most of their areas while boosting how customers feel inside the store. Over the years, this approach has built trust with clients worldwide, making Create a go-to for reliable setups that last.

Balancing Cost with Performance in Supermarket Freezer Investments

The steep price of commercial supermarket freezers goes beyond their scale. It includes detailed engineering, rule-following needs, power-saving thoughts, special builds, and a worldwide chain sensitive to changes. Initial outlays might look high, but picking good gear brings returns. These come from reduced running expenses, less chance of breaks, extended use periods, and stronger store looks.

FAQ

Q1: Why are supermarket freezers more expensive than residential models?

A1: Supermarket freezers are designed for continuous commercial use under strict temperature control requirements. They incorporate industrial-grade components that ensure durability, energy efficiency, and regulatory compliance—factors not required in residential units. This setup allows them to handle daily demands without faltering, which home units simply don’t need to do.

Q2: How do energy-efficient designs reduce long-term freezer costs?

A2: Energy-efficient designs minimize electricity usage through advanced insulation materials, variable-speed compressors, LED lighting systems, and smart defrost cycles—significantly lowering operating costs over time. By focusing on these elements, owners see quick payback on their investment, especially in high-use settings like busy supermarkets.

Q3: Can supermarket freezers be customized for different store layouts?

A3: Yes, many commercial freezer manufacturers offer modular configurations that can be tailored to specific store layouts or branding requirements—though this customization typically increases upfront investment costs. Such flexibility ensures the equipment blends seamlessly with the store’s design, improving both function and visual appeal for shoppers.