Maintaining proper freezer temperatures in supermarkets is a key part of food safety management. Keeping freezer temperatures steady is vital. It helps preserve the taste, texture, and look of frozen foods. More importantly, it stops harmful bacteria from growing. These germs can cause serious health problems. In most Hazard Analysis and Critical Control Point (HACCP) plans, frozen storage counts as a critical control point (CCP). So, constant temperature checks are a must for rules and daily operations. Agencies like the FDA and USDA require frozen foods to stay at or below -18°C (0°F). This keeps them safe and fresh for longer.

Standard Temperature Ranges for Supermarket Freezers

Supermarkets use strict freezer temperature goals to protect food safety. They also keep product quality intact. These goals come from solid research and common industry habits.

Industry Benchmarks for Commercial Freezer Settings

Most supermarket freezer units work at or under -18°C (0°F). This matches FDA and USDA rules for saving food. It stops germs and rot from happening. The FDA says frozen foods need storage that keeps them solid. That usually means -18°C or cooler. This level works well for many items, like ice cream or fish. Still, some products need tweaks based on how sensitive they are.

Ice Cream: It does best near -23°C (-10°F) for good texture.

Seafood and Meats: They stay fresh at -20°C to -23°C (-4°F to -10°F).

Pre-packaged Meals: These are okay at -18°C. But lower temps help for long storage.

Factors Influencing Temperature Setpoints in Supermarket Environments

Industry rules set the bar, but real freezer results can shift due to various outside and inside issues. For instance, how much product you pack in matters. Overloading blocks air flow. This can make some spots warmer. Also, opening doors often lets in warm air from outside. High room heat can strain the cooling machines. Bad insulation or poor air spread inside the unit leads to ups and downs in temperature. Many stores balance safety with saving energy. They use smart tech and better designs to cut power use while keeping things cold enough.

Implications of Inadequate Freezer Temperatures on Food Safety Protocols

Even small or short temperature slips can harm food safety a lot. They also hurt customer faith and rule-following.

Microbial Risks Associated with Temperature Deviations

If a freezer warms above -18°C, germs like Listeria monocytogenes might start to wake up. These bugs stay quiet in true cold. But they can grow in just a bit warmer spots. Changes in temp speed up germ growth. This happens most during thaw and freeze cycles that repeat. Bad germs like molds and yeasts spread too in poor cold. They ruin food taste. Plus, nutrients break down faster. Texture gets worse with these shifts.

Regulatory Compliance and HACCP Requirements

Inspectors check freezer records often in food safety reviews. HACCP sees freezing as a CCP. It demands exact notes and live tracking. Breaking rules can lead to expensive product pulls. You might face fines or lose good name. Tech for ongoing checks helps follow rules. It also tracks issues if safety problems arise.

We hold many quality check papers and tough factory tests. We stick to putting quality first. This promise matches rule needs and what buyers expect for safety.

Technological Solutions for Maintaining Optimal Freezer Conditions

Today’s supermarkets use tech heavily to watch and control freezer temps in many spots.

Monitoring Systems and Data Logging Technologies

New tracking tools beat old manual temp reads. Digital tools with warnings buzz staff right away if temps go off track. Cloud setups let bosses oversee chains from one place. They keep past data handy. Auto log systems cut mistakes from people. They stamp times on records without help. Such tools are key for meeting HACCP note rules.

Role of Energy-Efficient Refrigeration Equipment in Stability Control

Power-saving freezers give steady cool without hurting green or money goals. By picking top brand inverter compressors that experts trust, we make items that use less power. They run smooth and steady. You can cut electric bills by up to 50% in a year. Main tech bits include inverter compressors for even work with low power pull. Smart thaw times cut ice without big temp jumps. Even air fans stop hot areas by spreading cool air all through the unit.

Design Considerations for Supermarket Freezers That Enhance Food Safety Protocols

How you build supermarket freezer units matters a lot. It aids food keeping and easy shopping.

Cabinet Configuration and Airflow Management Strategies

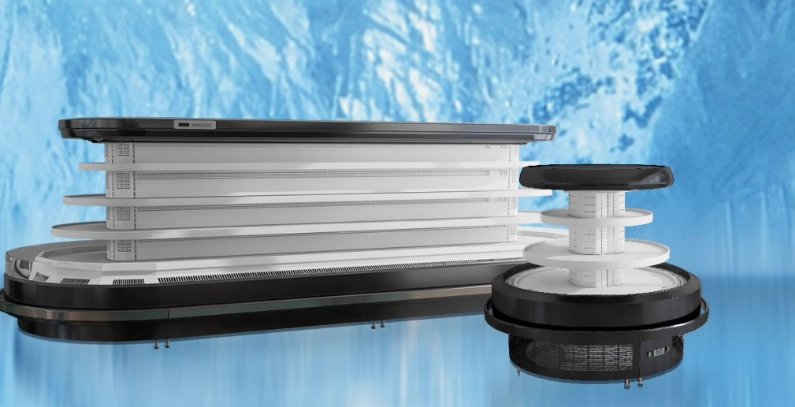

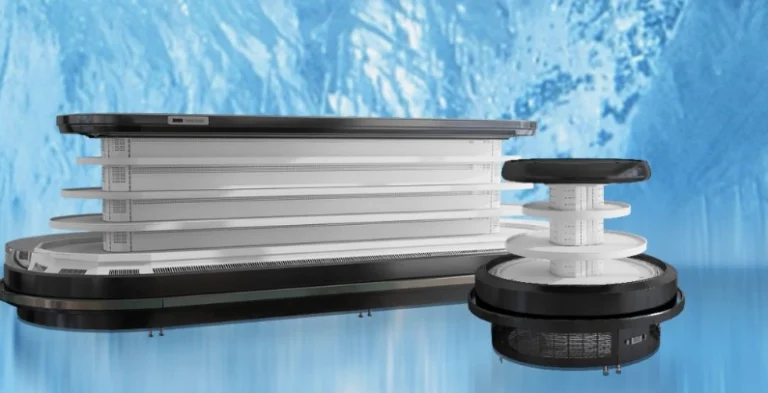

Choosing flat island freezers or tall deck units depends on store setup, how well you see goods, and temp plans.

Horizontal Island Freezers vs Vertical Multideck Units

Both types offer good points and downsides. Horizontal island freezers hold lots deep. They insulate well. But they need smart air plans. They take more ground space. Vertical multideck units let you see items clearly. Access is simple. Yet they feel ambient air more. Doors open often too.

| Freezer Type | Pros | Cons |

|---|---|---|

| Horizontal Island Freezers | Deep storage capacity; efficient insulation | Requires careful airflow design; more floor space |

| Vertical Multideck Units | Better product visibility; easier access | Sensitive to ambient air; higher door opening frequency |

All of the shelves in our products are adjustable to suit your needs. This setup aids air flow around various item setups.

Importance of Door Design and Access Frequency Control

Cutting air swap between inside and outside is vital. Self-closing doors stop cool loss when folks shop. Night covers hold cold after close. They save power. Sliding glass lids on islands cut open time for stock or looks. Freezer uses imported LOW-E double layers Glass Door with Electric Heating. This keeps views clear without fog. It holds inside cold well.

Create Refrigeration: A Trusted Partner in Commercial Freezing Solutions

In supermarket cooling options, Create Refrigeration shines as a solid all-in-one maker. They offer custom setups for power saving and food safety.

Overview of Create Refrigeration’s Capabilities

SHANDONG CREATE REFRIGERATION CO.,LTD. We sit in Xingfu Industrial Park, Binzhou City, Shandong Province, China. Our goods fit every country’s market. They reach first-level energy saving and level 1 use. Items run steady. They keep food safer. The firm gives full plans from idea to build. It uses green coolants like R290 and save-power parts. For 16 years, Create Refrigeration and its group with 12 branches has grown to China’s top one-stop buyer source. Welcome to view product details. Contact us for custom supermarket designs

Product Highlights Relevant to Supermarket Applications

Supermarket Combined Island Freezer Cabinets

Built for big frozen holds with steady temps in sections. Modular builds fit store shapes. They keep heat loss low.

Single Island Display Freezers for Frozen Foods

These give great item views with earth-friendly coolants. Low energy consumption: This product is static cooling system, which energy consumption is only 1/4 of the same volume of ventilate cooling island freezer.

Multideck Refrigerated Open Fridges

Great for milk goods or wrapped items that need even cool. Quick chill and steady temps boost food keep quality.

Summary and Key Takeaways

Handling supermarket freezer temps is a must in today’s stores. Keeping inside at or under -18°C meets world food safety rules. It guards buyer health too. Adding smart watch tools, power-saving parts, and smart unit builds boosts steady work. Teaming with trusted makers like Create Refrigeration gives stores rule-fit, power-smart, and grow-ready cold setups. These match changing field needs.

FAQ

Q1: What is the recommended operating temperature for supermarket freezers?

A: The industry standard is -18°C (0°F) or lower to ensure food remains safely frozen according to FDA guidelines.

Q2: How often should freezer temperatures be monitored in a supermarket setting?

A: Ideally, temperatures should be monitored continuously using automated systems with alerts; manual checks should be performed at least twice daily as a backup.

Q3: Can energy-efficient freezers maintain consistent low temperatures without compromising performance?

A: Yes, modern energy-efficient models use advanced compressor technology and smart defrost cycles to maintain stable internal conditions while reducing electricity usage.