In commercial refrigeration systems, the refrigerator holds an important job in keeping steady temperature checks, protecting items that go bad quickly, and improving the whole system’s output. As the need for safe and eco-friendly food storage increases, refrigerators have changed into something beyond just separate machines—they now form main parts of linked cold chain structures. From supermarket paths to factory cooking areas, how well they work affects food protection, power use, and following rules directly. Refrigerators function as integral units within broader refrigeration systems, where they not only keep goods at wanted temperatures but also connect with other system parts to make sure operations run smoothly and to lower power waste.

Classification of Refrigerators Within Refrigeration Equipment

Getting the hang of how refrigeration equipment gets grouped matters a lot for those who design systems and run them, since they want to put the best fix in the best place.

Defining Refrigeration Equipment Categories

Refrigeration equipment covers a wide field that takes in pieces like refrigerators, freezers, chillers, and display cabinets. The grouping often rests on three main things:

Application: commercial (e.g., supermarkets, convenience stores) versus industrial (e.g., cold storage warehouses).

Temperature range: from mild chilling to deep freezing.

Cooling method: static, ventilated, or air-curtain based.

Create Refrigeration mainly produces commercial supermarket refrigeration equipment, stainless steel refrigeration equipment, cold storage equipment and supermarket shelves. Such a range of products makes them fit well in various business situations.

Positioning of Refrigerators in System Architecture

Refrigerators can work as self-contained plug-in pieces or get built into far-off systems that share compressors and condensers. In supermarket settings, people often link them to main cooling setups so they keep even work going across different sections. Refrigerators go well with other key parts, like compressors that move refrigerant along the cycle, condensers that give off heat, and evaporators that take heat out of inside areas.

Core Components and Technical Operation of a Refrigerator

To see a refrigerator’s part in how the system does, it helps to know its inside workings and heat rules.

Key Mechanical Elements in a Refrigerator Unit

The basic parts inside every refrigerator cover compressor: compresses and circulates refrigerant throughout the system. Condenser: Releases absorbed heat to the surrounding environment. Expansion valve: Regulates the flow of refrigerant entering the evaporator. Evaporator: Absorbs heat from the refrigerator’s interior to maintain low temperatures. Our products have comprehensive applications such as efficient refrigeration systems, stable air curtain systems, environmental friendly refrigerants, and foaming agents, ensuring high-quality component integration.

Thermodynamic Cycle in Refrigerator Operation

The usual heat rule in play is the vapor-compression cycle, and this process depends on changes in the refrigerant’s state where evaporation pulls in heat from the inside area while condensation lets that heat out to the outside. Newer types try to make this process better to boost power savings.

Integration of Refrigerators in Commercial Refrigeration Systems

Today’s refrigeration systems do not stand alone anymore; rather, they link up as central points in bigger shop networks.

Role in Supermarket and Retail Applications

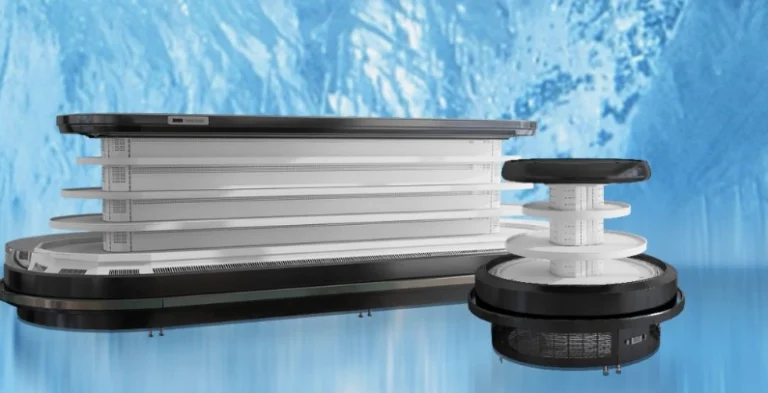

In supermarkets, refrigerators handle two jobs: saving products and pulling in shoppers. Pieces like multideck open chillers get made for easy seeing and reaching. Supermarket Freezer multideck refrigerated open fridge fruits dairy display cabinet display chiller cabinet is one good case that helps with showing products visually while keeping the cold chain solid. Island freezers stand as another usual type that gives side-to-side access, which fits frozen items such as seafood and ice cream.

Synchronization with Centralized Cooling Infrastructure

Instead of just using nearby compressors, lots of commercial refrigerators tie into main compressor racks or condensing units, and this setup lets them handle temperatures evenly over many pieces while helping the whole system save on power.

Energy Efficiency Considerations for Refrigerator Units

Power use counts as a big worry in commercial refrigeration because operations run on such a large scale.

Compliance with Energy Standards and Certifications

Refrigerators used in business places must follow rules like ENERGY STAR® and FEMP guidelines. Federal laws and requirements mandate that agencies purchase ENERGY STAR-qualified products or FEMP-designated products, ensuring life cycle cost-effectiveness.

According to FEMP data:

| Model Type | Energy Use (kWh/year) | Lifetime Cost Savings |

|---|---|---|

| Best Available | 394 | $480 |

| ENERGY STAR® | 602 | $300 |

| Conventional | 949 | – |

These savings justify investing in high-efficiency models despite slightly higher upfront costs.

Design Features That Enhance Efficiency

Refrigerators today incorporate various technologies aimed at minimizing energy usage:

Advanced Insulation Materials

Using eco-friendly foaming agents like C5H10 reduces thermal leakage and compressor workload.

Variable-Speed Compressors and Fans

Adjust their operation based on real-time demand for cooling — ideal for mixed load environments.

LED Lighting Systems in Display Units

Standard LED lamp, more bright, better looking on foods also reduces internal heat gain compared to traditional lighting methods.

Application-Specific Refrigerator Configurations

Different retail formats require tailored refrigeration solutions.

Island Freezers for Frozen Food Merchandising

Supermarket combined island freezer commercial cabinet freezer for sale features large transparent windows and energy-saving inverter compressors, offering an ideal layout for self-service frozen food sections.

Multideck Open Display Cabinets for Dairy & Produce

These vertical cabinets use air curtains and adjustable shelves to showcase fresh items while maintaining temperature consistency. Plug-in Floor Standing Air Curtain Multidecks offer LED lighting per shelf and auto-defrost functions — boosting both energy savings and product visibility.

Create Refrigeration: A Reliable Supplier of Commercial Refrigerator Solutions

Among global providers of refrigeration solutions, Create Refrigeration stands out through its integrated manufacturing capabilities and commitment to sustainability.

Overview of Create Refrigeration’s Product Offering

Create Refrigeration mainly produces commercial supermarket refrigeration equipment, stainless steel refrigeration equipment, cold storage equipment and supermarket shelves, with an extensive lineup including island freezers, glass door chillers & freezers, multidecks open chillers, upright cabinets, and more. Explore their full product range at Create Refrigeration.

Technical Expertise and Customization Capabilities

Clients can submit CAD layouts for tailored design services. Provide us with your supermarket CAD drawings, and we can create a 3D design for your supermarket — an offering especially valuable during new store planning or renovation phases.

Global Reach with Local Support Services

With overseas warehouses and service centers across 70+ countries, Create Refrigeration offers DDP logistics options and 24/7 after-sales support. Contact them for inquiries or project consultations.

FAQ

Q1: How does a commercial fridge differ from a residential one?

A: A commercial refrigerator is engineered for higher durability and performance. It operates continuously under heavy use, recovers temperature faster after door openings, has larger capacities, and complies with food safety regulations — unlike domestic models built for intermittent use.

Q2: What’s the best way to reduce a commercial fridge’s energy consumption?

A: Regular maintenance (like coil cleaning), using ENERGY STAR® certified models, installing LED lighting, ensuring proper door seals, and choosing units with inverter technology significantly reduce power use over time.

Q3: Can I use a single fridge model for both chilled drinks and frozen goods?

A: No. Chillers (like Glass Door Chiller & Freezer) are suitable for beverages or produce at 2–8°C; freezers maintain -18°C or below — suitable for ice cream or frozen meats. Choose based on your product type to ensure optimal preservation.