Ice buildup stands as one of the most stubborn and expensive problems in running commercial display freezers. Too much frost harms the cooling performance of the unit, and it also boosts energy use a lot. This results in greater running expenses. When ice gathers on evaporator coils or clogs air routes, it blocks smooth airflow. Consequently, it leads to irregular temperature areas. In the end, this impacts the quality and safety of stored goods. Moreover, frost on inside walls and glass doors can hide products from view. Thus, it weakens the appeal of displays for shoppers.

The way a freezer is built matters greatly in tackling these troubles. Modern commercial freezers include smart airflow setups, better insulation, and clever defrost tools. These features help control ice growth ahead of time. They also improve lasting dependability. As a result, companies can uphold food safety rules. At the same time, they make the most of energy. For more than twenty years, Create Refrigeration has led the way worldwide in the cold chain field, who provide fresh and eco-friendly cooling options made for shops and food service spots. Thanks to their OEM/ODM skills and emphasis on green coolants like R290, they supply tailor-made display freezers. These blend top-notch work with low energy needs, and their gear gets used in over 70 nations. A strong global setup and years of know-how back it up.

How Does Airflow System Design Reduce Ice Formation?

Managing airflow lies at the heart of good freezer planning. Even flow of cool air across the whole space cuts down on uneven temperatures. These differences often spark spotty moisture buildup and freezing. Strong fans paired with smartly placed channels keep this balance steady.

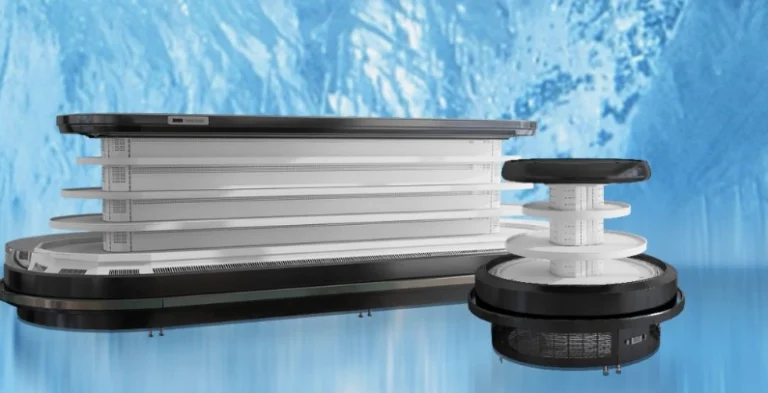

Good air movement stops moisture from forming on evaporator coils and inner parts. If the flow gets interrupted—say by stuffed vents or bad fan spots—damp, warmer air might hang around in places, which causes ice to develop. Even flow also fights temperature layers. It avoids hot areas that might start extra compressor runs. Those runs add to water gathering. Items like the Supermarket Freezer Multideck Refrigerated Open Fridge come with layered shelf air systems. They include auto-defrost tools, too. Both keep a steady chill in every section.

Are Door Designs and Seals Contributing to Frost Issues?

Opening doors often causes big jumps in inside wetness. Warm outside air rushes in during these times. It then turns to water fast on chill spots, creating frost. The door setup decides how much outside air sneaks inside while working.

Glass with two or three layers plus coatings against moisture cuts down on surface ice. These setups work as heat blocks. They stop at the point where dew forms from touching cold areas. Plus, magnetic seals hold tight even after many opens and closes. Hinges that shut on their own shorten the time doors stay open. This keeps the chill steady inside.

In units with weak seals, repeated door use speeds up water entry and ice growth. That’s why things like low-E glass and electric warming prove vital. They keep their sights clear and stop blurring from dampness.

Does Evaporator Coil Position Affect Frost Accumulation?

Where evaporator coils sit and how big they are shape how well a freezer chills its space. If a coil ends up near wet areas or spots with no air movement, water is more prone to settle on its parts.

The spot of the coil influences how smoothly cold air spreads in the unit. Bigger coils might look helpful at first. However, they can cause quick runs that skip full melting of ice. Over time, this lets frost pile up. Smaller coils, meanwhile, can’t handle heat loads well. This is especially true in damp weather. Matching the right coil size with sharp controls lets the cooling adjust better. It avoids problems from freezing and thawing too much.

Which Defrosting Method Works Best for High-Use Freezers?

Clearing ice through defrost goes beyond just getting rid of it. The goal is to do so without hurting stored items or wasting power needlessly. Various methods suit different setups, and picking the right one depends on daily demands.

Hot Gas Defrost pulls hot, high-pressure coolant from the compressor’s output to thaw frost fast. In busy spots with lots of use, it cuts down on power surges better than electric options. This keeps operations smooth without big energy hits.

Electric Defrost makes use of heating wires turned on by clocks or detectors. It’s straightforward to set up and run. Yet, it needs careful watching to prevent too much heat near the goods from the coils. Overdoing it could warm products unintentionally.

Off-Cycle Defrost taps into room warmth when the compressor pauses, and this method shines in places with little ice trouble. But for freezers that see heavy action, it falls short in keeping up with the buildup.

How Important Is Material Selection in Preventing Frost?

Thet materials that go inside decides how steadily a freezer holds its cool and fights ice growth. Choices here directly shape the unit’s ability to stay dry and efficient over long periods.

Materials that don’t conduct heat easily cut down on links where cold meets warm, sparking water drops and frost. Inside covers from plastic mixes handle heat shifts better than plain metal ones. Shelf setups should steer clear of routes that let heat in or let dampness gather. This keeps the whole interior more uniform.

Insulation works hand in hand with that. Thicker foam from polyurethane holds heat out more firmly. It eases the compressor’s job and lowers the chances of ice forming. For freezers like island types open on several sides, this proves extra key, and it helps them perform well despite more exposure to outside air and temperature swings.

Do Smart Controls Improve Defrost Accuracy?

Controllers with built-in smarts prove crucial for running defrost based on what’s happening right now, not just set times. These advanced systems tweak cycles using live data on dampness, how the unit gets used, and coil chill levels. By doing so, they avoid waste from too-frequent or missed clears.

Where sensors sit matters just as much. If placed incorrectly, they might get faulty reads on coil temps or miss small freeze spots, and this could lead to overdoing defrost, which wastes energy, or underdoing it, which lets ice linger. Proper setup ensures the system responds exactly when needed.

Models such as the Supermarket Combined Island Freezer have microcomputer temp controls. These show LED lights and run auto defrost for sharper results. They make daily checks easier and keep everything running at peak without much hassle.

How Do Cleaning Features Help Mitigate Ice Buildup?

Freezers built smartly make cleaning straightforward for teams. Panels that open easily let workers reach evaporator coils without taking apart big pieces, and this quick access means issues get spotted and fixed early, before small problems turn into bigger ones.

Handling water runoff counts too. Pans with a good slope guide liquids away so they don’t pool and turn back to ice inside. Surfaces inside that are smooth and non-stick also shed water better after wipes. No corners for grime or moisture to hide in. All these parts together cut time lost to hand-clearing ice or urgent fixes from clogged paths or frozen bits. Staff can focus more on serving customers, and the unit stays reliable day after day.

How Does Store Environment Influence Ice Formation?

What’s around the freezer outside affects how it acts inside quite a bit. Places with lots of damp air bring in more water each time doors swing open, and this speeds up how fast frost appears and grows.

The shop’s setup plays a part as well. Putting freezers in tight, stuffy corners hurts how well condensers work. That indirectly raises wetness levels within the unit by making cooling less effective overall.

Good airflow around the machines helps compressors run more smoothly, and it also keeps moisture from building up too much. Simple tweaks like spacing units properly can make a real difference in long-term performance.

What Operational Practices Can Staff Follow to Prevent Ice?

The finest freezer design won’t hold up if folks don’t handle it right. Teaching workers to keep air paths clear from boxes or bags ensures the flow stays open inside. Blocked vents lead straight to uneven chill and faster ice spots.

Cutting down on how often doors open—particularly in busy times—limits fresh air from sneaking in. Less intrusion means less quick water forming on cold parts. One good step is to plan refills for quieter hours. This way, the unit doesn’t face constant warm blasts that build frost layer by layer.

Create Refrigeration: A Trusted Partner in Commercial Refrigeration Solutions

Boasting more than 25 years in cooling tech and reaching over 70 countries with support, Create Refrigeration offers solid commercial display freezer setups. These focus on steady work and easy upkeep. Their lineup covers multideck open chillers to special island freezers. Each one packs in strong anti-frost tools for the best results possible.

They show real care for the planet through using R290 coolants and power-saving wraps. OEM/ODM help lets them craft pieces to fit exact looks, sizes, or save goals. This positions them as a key ally for businesses growing their shop cooling setups over time. With global reach and expert backing, clients get gear that lasts and performs without constant worries.

Summary of Key Insights on Managing Ice Buildup Through Freezer Design

Taking a full-view strategy matters a lot, which includes fine-tuned air routes, strong seal setups, exact control tools, top insulation picks, simple clean paths, and wise shop routines. All these work together to handle ice growth in commercial display freezers well. Blending solid build work with sharp tech keeps things stable for the long haul.

FAQ

Q1: How does poor airflow contribute to excessive ice buildup?

A1: Inadequate airflow causes uneven temperature zones where humid air can condense on colder surfaces like evaporator coils or shelves, leading to localized frost accumulation over time.

Q2: What type of defrost system is ideal for high-volume commercial freezers?

A2: Hot gas defrost systems are typically preferred in high-demand settings due to their rapid ice removal capability without significantly raising internal temperatures or interrupting operation cycles.

Q3: Can insulation quality really impact how often a freezer needs defrosting?

A3: Yes, better insulation minimizes external heat gain, which helps maintain stable internal temperatures—this reduces condensation rates that lead to frost formation inside the unit.